Innovex's 5,000-sq-m facility in the Dammam 2nd Industrial City

Innovex's 5,000-sq-m facility in the Dammam 2nd Industrial City

With the opening of the new engineering and operational centre, the company can now support all its products in Saudi Arabia with greater efficiency and speed than ever before

Innovex Saudi Arabia has enjoyed operating in the Kingdom of Saudi Arabia for over seven years. As a provider of critical downhole products, Innovex has responded to the rapid growth and demand in the Kingdom.

The Innovex operational footprint has doubled in size with the new Engineering and Operational centre based in Dhahran. The first-in-class operational infrastructure is over 2,000 sq m with engineering support, assembly, pressure testing and torque capabilities.

John Ray, Vice-President of Eastern Hemisphere, comments: 'Opening this new facility means we can now support all Innovex products in KSA with greater efficiency and speed than ever before. We're proud to be investing in our business and continuing to provide first-class service to all our customers in the Kingdom of Saudi Arabia.'

|

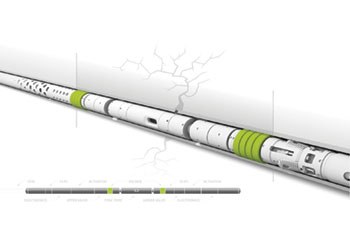

The SelectSET Ranger Linger Hanger allows it to be reamed-in and |

In addition to the operational footprint expansion, Innovex has invested in long-term growth in Saudi Arabia by acquiring a new industrial manufacturing facility in the 2nd Industrial City.

The 5,000-sq-m facility will be an API Certified, premium manufacturing and assembly facility for liner hangers along with completion packers, float equipment and ESP penetrators.

Recently, in collaboration with the Aramco Drilling team, the Innovex Saudi Arabia team has achieved multiple milestones, which add significant value.

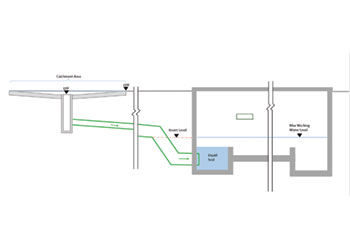

The Ranger/Scout Liner System was utilised in a single trip, full-bore, off-bottom cemented liner including 12 Innovex Masterflow ICDs and 8 I-Pack Open Hole Packers.

This was the first single-trip system ever run in KSA that featured a full ID to allow for a single cleanout run before the well is put on production. The innovative design eliminated two trips in total, reducing significant rig time and savings.

Additional KSA success includes the deployment of the Mechanical Combo tool in a multi-stage cementing application.

|

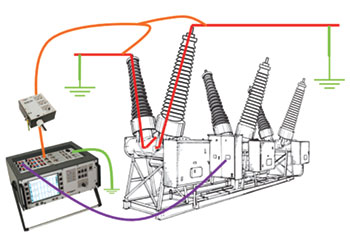

Innovex's new engineering and operational centre in Dhahran offers engineering |

The tool eliminated CCA pressure and enabled fast drill-out of the casing shoe track, demonstrating operational and engineering advantages to the operator.

Wells across the globe are becoming more challenging and complex. Innovex has developed the 'Select Set' Mechanically Locked Liner Hanger system to tackle the harshest of environments.

Specifically designed for wells with heavy mud weights and high circulation pressures, the Select Set has been successfully deployed in multiple wells across KSA.

The mechanical lock design ensures that the hanger cannot be prematurely set while being deployed in these challenging well conditions.