Suhail Engineering designs and manufactures for many industries

Suhail Engineering designs and manufactures for many industries

The group holds sustainability as a core value and has a continuously evolving strategy that includes initiatives in localising skills, promoting quality manufacturing, and environmental responsibility

Over the last eight years, Qatar-based Suhail Industrial Holding Group has grown into a diverse industrial conglomerate with interests ranging from its initial capabilities in recycling through to the more recently gained capabilities of complex engineering to offer innovative solutions from Qatar to the global market.

It produces and exports processed non-ferrous metals, stainless steel and plastic from Qatar to more than 25 countries markets.

The group boasts a collective metal production capacity of over 100,000 metric tonnes per year and a collective plastic production capacity of over 10,000 metric tonnes per year.

|

Scrap metal is turned into products using innovative ways |

Meanwhile, its network comprises 13 factories covering recycling, plastic, paper, oil and gas, metal and automotive, and operate 7 sales offices including in but not limited to Qatar, the UK, China, South Korea, and Ethiopia.

The company employs advanced technology in its facilities, ensuring efficient, environmentally friendly operations and high-quality products tailored to client specifications.

'Suhail’s capabilities are broad and wide, and with an extensive network of subsidiaries, the group has firmly established itself as the leader of field of recycling in Qatar and the region,' says a company spokesman.

Suhail has a diverse range of factories that use the latest innovative technology to get the highest quality products and services. These include:

• Suhail Battery Recycling Factory: Used car batteries are collected here and recycled into their primary raw materials (lead, plastic and acid). The factory has an annual production capacity of 50,000 tonnes. Additionally, the factory supplies Suhail Plastic Factory with recycled plastic.

|

• Suhail Batteries Industries: This facility produces batteries for passenger cars and trucks using lead-acid technology, in various sizes and measurements. It uses recycled lead and plastic from used batteries acquired from within the local market to manufacture new batteries.

Engineered in Qatar, NASK automotive batteries are designed to provide the proper level of power and durability for every type of vehicle, including cars, bus and trucks. The factory has an annual production capacity of 1,000,000 lead acid batteries using the latest technology and complying with universal standards.

• Suhail Metal Castings Factory: The facility employs two production methods: At the green sand-casting foundry, metal is melted in induction furnaces and then poured into sand molds. These are then filled and pressed on metal patterns and shaped into the final product. The sand molds are formed using forming machines that mix sand materials.

|

On the other hand, at the Investment Casting Facility, the patterns are shaped using wax injection machines and then assembled and moved to the robotic shelling system, where the shells are automatically prepared before moving them to dewaxing then shell firing and finally to metal pouring area. This facility has an annual production capacity of 50,000 tonnes.

• Nask Brakes Industries: This facility manufactures brakes for light and heavy vehicles by mixing different components, compressing, thermal treatment, and packaging. These brakes are free of asbestos and are at the forefront of the market with sustainable and innovative structural integrity. The factory has an annual production capacity of 1,000,000 sets.

• Suhail Aluminum Factory: This leading industrial company, committed to a sustainable future, turns aluminum scrap into products using innovative and efficient ways. It produces high quality billets, ingots, and sows for the local and international markets, and boasts an annual production capacity of 30,000 tonnes.

|

Suhail Industrial Holding Group employs the latest production methods at its |

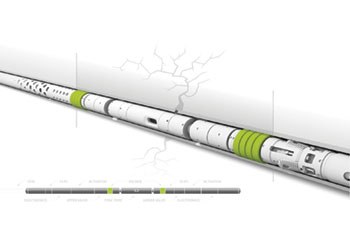

• Suhail Bronze Factory: It has two horizontal multi-strand casting lines and horizontal centrifugal casting equipment to make bars, tubes, and profiles from bronze in different shapes.

• Suhail Copper Factory: This first-of-its-kind facility in the region produces copper bars, bronze, and copper ingots of various sizes, measurements, purities and specifications, according to the demand of customers worldwide. The factory is fully fitted with automatic lines, advanced process controls, and the latest in copper-machining technology, and has an annual production capacity of 50,000 tonnes.

• Nask Metal Industries: This facility creates metal structures using techniques that include cutting, forming, general machining, welding and assembling. Then planning is done with the manufacturing department for production planning, and typical projects include stand-alone structures and metal structural parts for buildings, heavy equipment, stairs, scaffoldings, platforms, tanks, and pressure vessels. It has an annual production capacity of 10,000 tonnes.

• Nask Plastic Industries: This distinguished leader within the industry houses the latest plastic mold injection technology from a German company to produce 9,000 tonnes of products every year. It also has an in-house testing laboratory to maintain high-quality production.

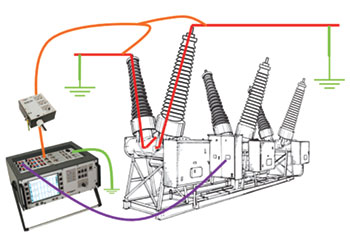

• Suhail Engineering Industries: This facility designs and manufactures a wide range of engineering products for many industries, such as the engine and automobile industry, pump industry, and oil and gas.

It used high-speed CNC machines to fabricate and assemble 70,000 tonnes per year of high-precision and complex products for the local and global agricultural, oil, and gas, aerospace, automotive sectors.

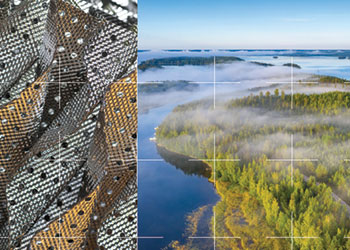

• Suhail Geotextile Factory: Geotextiles of varied thicknesses and weights are produced in this facility for use in infrastructure, streets, waterproofing, etc. The factory has partnered with the Italian AUTEFA and boasts up a maximum production capacity of 24 tonnes per day.

• Nask Paper Industries: This facility produces jumbo rolls of hygienic paper by processing fibres extracted from tree pulp and then mixing them with water and chemicals. It has partnered with the Italian company, Toscotec, and has a maximum production capacity of 75 tonnes of tissue paper per day.

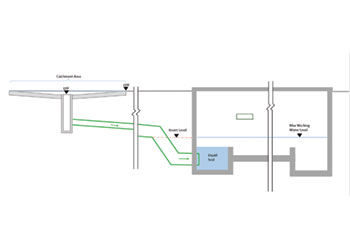

• Suhail Global Logistics Services (SGLS): This company handles loading/offloading from Hamad Customs, Hamad Seaport, and from New Industrial Area. It provides customers transportation using flat trailers for full loaded containers and bulk loose cargo for delivery at various zones in Doha. It has a fleet of 80 heavy vehicles including over 35 Mercedes Actros, heavy trailers and about 46 equipment including for special loading/off-loading equipment for transporting light or heavy cargo.

The Suhail Industrial Holding Group supports Qatar’s National Vision 2030 and is committed to localising skills, promoting quality manufacturing, and environmental responsibility.

The group holds sustainability as a core value, and in 2022, it established a ‘Sustainability Program Strategy’, which is continuously evolving based on the ever-changing community and environment. The strategy includes initiatives in each sustainability pillar area, ensuring that the group remains committed to its core values.