Saudi AramcoÕs refining sector ... long line of achievements

Saudi AramcoÕs refining sector ... long line of achievements

SAUDI ARAMCO has a proud history of achievements, and the year 2000 proved no different in the company's startling development, according to president and CEO Abdallah S Jum'ah.

In his review of last year, Jum'ah said that the company had moved ahead to meet its obligations and prepare for future energy demand by meeting, or exceeding, oil, gas and petroleum products targets for the year.

The start of a new century has been marked by a growing worldwide acceptance of electronic networking in commerce and business operations at all levels. Saudi Aramco last year developed internal and external networks to streamline and speed up hydrocarbon and other operations, said Jum'ah.

These networks also facilitated decision-making and enhanced relationships with suppliers and customers.

In the Marjan field in the Gulf, Saudi Aramco installed a VSAT satellite communication system at Gas Oil Separator Plant 2 (GOSP-2), establishing a cost-effective and reliable communications link between the facility and the corporate network.

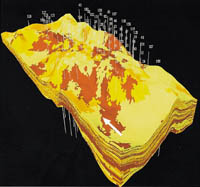

Saudi Aramco explorationists located 5.9 trillion cu ft of non associated gas reserves South and West of the giant Ghawar field last year. Two new gasfields were also discovered by the company at Manjurah and Ghazal, finds which brought to 87 the total number of Saudi Aramco's oil and gas fields.

Saudi Aramco made three new gas discoveries in formations beneath existing fields in Niban, Hawiyah and Mazalij.

As part of the Gas Expansion Program at the company, Saudi Aramco last year commissioned a new pipeline network supplying sales gas to three new Saudi Electric Company (SEC) power plants in the Riyadh area. This project will reduce the use of crude oil as power plant fuel in the Kingdom.

Ju'aymah Gas Plant also received new technologies including neural network modelling and multivariable controls, to improve plant performance and enhance revenues.

New Khuff facilities were commissioned at Shedgum and 'Uthmaniyah Gas Plants, according to Jum'ah. These projects increased gas processing capacity to 2.4 billion cu ft per day and 2.5 billion cu ft per day respectively.

A new high pressure gas treating facility and other additions at Berri Gas Plant boosted capacity to more than one billion cu ft per day.

Abqaiq Plants, Saudi Aramco's main onshore oil processing facility, improved its operations with a sweeping programme which integrated operational and human relations factors to enhance performance in all aspects of plant operation and maintenance.

Last year, Saudi Aramco's Oil Supply Planning and Scheduling (OSPAS), working with other organisations, completed the construction of a Disaster Recovery Site (DRS), a facility equipped with back-up computers, network and voice communications which enable the critical operations of the Operations Coordination Center (OCC) to continue even if the main control room is disabled in a disaster.

The OCC oversees and coordinates reliable production and delivery of Saudi Aramco's complex flows of hydrocarbons. Manned around the clock, the OCC is one of the largest, most sophisticated real-time command centres in the world, monitoring, controlling and directing the throughput of billions of dollars worth of crude oil, gas and petroleum products.

The phase out of leaded gasoline at the end of last year led a long line of achievements in the refining and distribution sector, said Jum'ah.

Ras Tanura refinery concluded last year its South Plant start-up activities with performance tests. Among other projects at the refinery were the installation of new terminal computer systems at the Sea Island facility, increasing flow accuracy and providing better plant controls.

Riyadh refinery received a new digital control system, which replaced existing control systems to improve measurement of process variables, real-time data acquisition and better overall monitoring and control of all processes.

Jeddah refinery replaced the instrumentation of its Crude Unit No.2, fluid catalytic cracker, platformer and merox units with the latest distributed control system (DCS) technology.

Yanbu refinery conducted upgrades and maintenance, and installed a state-of-the-art on-line analyser and DCS for its gasoline blender, said Jum'ah.

Rabigh refinery also increased its year-round maximum sustained capacity from 400,000 to 425,000 barrels per day (bpd) of crude oil, providing increased cost efficiency and helping to satisfy future local demand and product exports.

Saudi Aramco maintained its global readiness last year in the event of an oil spill, assuming key roles in two major drills during the year. A new pollution control vessel - equipped with advanced oil spill and marine pollution equipment - also adds significant hardware to the company's environmental protection capabilities.

Saudi Aramco continues to upgrade efforts to protect the ecosystems in which it operates. Last year the company closely monitored and assessed the effects of its industrial facilities on surrounding areas, improving environmental performance.

The company took part in an environmental workshop on coral reef bleaching in relation to its plans to develop areas offshore the country's West coast.

The number of Saudi Aramco employees totalled 54,501 at the end of last year, 46,315 (or 85 per cent) of whom were Saudi nationals. The company, said Jum'ah, has continued to attract new Saudis from different educational backgrounds, training and developing them to become fully qualified to perform the various jobs in the professional, industrial and administrative segments of the workforce.

Some 10 million man-hours were invested in workforce training and development last year. The use of e-learning and distance learning technologies was enhanced by increasing the learning opportunities available to employees at desktop computers.

In the IT sector, company specialists provided some 35,000 users in more than 1,000 buildings throughout the Kingdom with efficient and reliable computer and networking services and solutions.

Web-based technology was introduced, giving users the ability to promote and share proprietary information across business lines. More than 200 Intranet websites were in use at the end of the year.

The company's implementation of the first SAP modules last year provided increased productivity through improved data availability, quality and reduced processing time.

The company completed Phase I of a new Lab Research & Development Center (LR&DC) in Dhahran, providing 12,000 sq m of state-of-the-art research facilities to support company operations.

Saudi Aramco continued last year its policy of promoting the development of the Kingdom's economy on local and national levels by awarding most of its contracts to Saudi-owned or joint venture companies. During the year, 86 per cent of the company's purchases came from Saudi factories or Saudi importers, and Saudi factories supplied more than $330 million of those purchases. At the end of the year, more than 11,000 contractors were registered with Saudi Aramco with up-to-date information maintained in a computerised Contract Information System.

Saudi Aramco subsidiary Vela International Marine Ltd transported about a quarter of Saudi Aramco's crude exports, according to Jum'ah. It shipped almost 2.6 million bpd of crude and 370,000 bpd of refined products in the year.