Saudi AramcoÕs Research and Development Centre in Dhahran

Saudi AramcoÕs Research and Development Centre in Dhahran

SAUDI ARAMCO has long been considered a pioneer in the development of petroleum technology.

The first phase of a new Research & Development (R&D) Center building project which was inaugurated in Dhahran earlier this year is expected to boost the R&D sector in Saudi industries in general and the petroleum industry in particular.

The centre will eventually employ 350 engineering scientists during the first two phases of development, according to reports.

This latest investment follows completion of Phase 1 of the company's Lab Research & Development Center (LR&DC) in Dhahran last year.

The LR&DC is a 12,000 sq m state-of-the-art research facility which supports company operations.

The centre provides high bay space to house large-scale simulation systems such as a catalyst pilot plant and sanding and formation damage equipment.

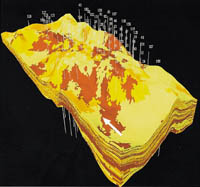

It also provides the opportunity to expand and upgrade research equipment to support exploration, producing and refining operations.

Saudi Aramco says that its scientists and researchers often develop additional value through patentable discoveries as they work to meet the challenges associated with the company's complex operations.

The company has an Intellectual Assets Management (IAM) team to manage and protect company-developed assets and commercially exploit those developed by company technology and research.

This initiative, which started last year, centralises the processing of patents and copyrights so that intellectual properties can be licensed and developed for marketing. This in turn has great potential to increase future revenues and generate significant cost savings, according to the company.

Saudi Aramco works continuously through R&D to meet the highest standards of quality for its products.

At the Ras Tanura Laboratory (RTL) responsibilities include technical support and analysis of products.

The RTL operates and supervises on-line analyser quality control around the clock for all Ras Tanura plants, an even more significant function since Ras Tanura refinery switched from batch-blending to on-line blending.

In addition to the refinery's facilities, RTL also serves Ras Tanura Terminal's tank farms, Ju'aymah Gas Plant and all Eastern Distribution bulk plants, performing an average of 37,000 tests per month.

It is also responsible for calibrating and certifying all Saudi Aramco laboratory and plant testing thermometers, hydrometers, and centrifugal tubes.

The construction of the new RTL was spurred by the major upgrade programme at Ras Tanura refinery.

The 4,500 sq m facility is connected to an advanced computer system - the Laboratory Information Management System - linking it to all refinery plants and related administrative divisions.

After completion of lab analyses and review, results are sent directly to the concerned organisations, according to the company.

Among the most important pieces of RTL equipment are octane engines, which measure gasoline-combustion efficiency; gas chromatographs, used to determine the components of samples; and inductively coupled plasma-mass spectrometer analysers, which determine the percentage of metals in various types of water used in refining operations and for drinking.

RTL also operates a miniature fractionation tower. It is used to study crude oil distillation and help determine the product quantity and quality - which benefits marketing and planning.