The Saudi Aramco dimensional visualisation centre in Dhahran

The Saudi Aramco dimensional visualisation centre in Dhahran

MEETING PRODUCTION targets at a company of the scale of Saudi Aramco takes special logistical planning and optimisation of resources.

Saudi Aramco's capability to carry out supercomputer-aided exploration and production activities received a massive boost earlier this year when hardwares and softwares were installed at the company's Exploration and Petroleum Engineering Center (EXPEC).

The project has doubled the EXPEC Computer Center's (ECC) supercomputing capacity to support increased oil and gas exploration and field activities and will enable Saudi Aramco to meet projected growth in oil and gas demand and optimise field development.

The operation and administration of the new supercomputers is handled in-house.

Two upgrades were carried out using IBM computers - one for seismic processing and the other for reservoir simulation - creating in the process one of the most powerful supercomputing geoscience centres in the oil industry.

The hardware will boost ECC capacity to process seismic data from exploration and development crews, and will hugely improve the resolution of reservoir-simulation models which help pinpoint where to drill wildcat wells and optimise hydrocarbon production in the Kingdom, according to the company.

The costs of this computer power, which represents a sizeable investment on the part of Saudi Aramco, is offset by the savings which the company can make in having informed decisions about its drilling and exploration, thus providing important economic leverage.

The seismic processing platform has 512 processors, essentially CPUs arranged in nodes. Seismic data is kept on a huge, online, magnetic disk farm comprising almost 7,000 disks with a combined capacity of 190 terabytes.

In 1993, ECC had just one terabyte of storage capacity, compared with today's online storage capacity of 225 terabytes, a figure which is set to grow.

The ECC's new platforms incorporate massively ''parallel'' processing configurations, which work simultaneously instead of sequentially to achieve computational speeds many times faster than even the most powerful sequential machines. This technology significantly lowers costs and shortens process cycle-time.

New seismic technologies which are ten times more computer-intensive than conventional seismic processing are making progress, improving Saudi Aramco's ability to image deep targets. But this computer-intensive technology became practical only recently with a major decrease in the cost of computer power.

Pre-Stack Time Migration technology, for example, improves the image quality and resolution of seismic data, especially for deep targets, reducing exploration risks and increasing the success rate for exploratory gas drilling. The new imaging techniques are said to be especially important with the current exploration targets at Saudi Aramco: difficult-to-image, deep nonassociated gas reservoirs.

The reservoir-simulation supercomputer platform is now used mainly to run Saudi Aramco's parallel reservoir simulator, called POWERS, which was developed in-house.

This supercomputer comprises more than 180 processors, which process data simultaneously, and more than 12 terabytes of disk space.

POWERS provides extremely high-resolution processing. In the past, Saudi Aramco was only able to simulate portions of large reservoirs such as the Arab D in the Ghawar field, the world's largest oil reservoir, at one time. Using POWERS and the new hardware, the company can now simulate such huge reservoirs all at once, significantly improving data quality and resolution.

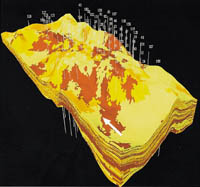

Advanced computer technology is a common link between 3D seismic data acquisition, processing and interpretation, the size and complexity of data volumes collected today in a 3D survey far exceeding the capacity of computers which were considered state-of-the-art just a few years ago.

The need for increased computer power for surveys has also driven the development of new processing and interpretation software which enhances subtle reservoir features, thus providing a clearer view of a reservoir's overall dimensions and properties and its potential behaviours during the drilling and production processes.

The new technology will, according to Saudi Aramco, pay off in optimised rates of new-well drilling, improved management of mature reservoirs, lower facilities-planning costs, increased ultimate oil recovery and new hydrocarbon reserves.

EXPEC has played a crucial role over the years in Saudi Aramco's exploration successes.

Petroleum engineers have used the facility to chart increases in crude production capacity in the Kingdom and in mapping the delivery of more gas into the Master Gas System (MGS).

Since it opened in 1982, EXPEC and its associated Laboratory Research and Development Centre have enabled the company to essentially eliminate its dependence on upstream technological support from other oil companies.

Exploration data collection, processing and interpretation all take place within relatively close proximity, enhancing coordination, improving efficiency and speeding up the pace of work.

The use of 3D seismic technology has benefitted both exploration and production.

Because it involves a much higher density field coverage than two-dimensional seismic data acquisition, and because of the large size of Saudi Arabia's fields, 3D seismic surveying generates huge volumes of digital data which is processed and analysed at EXPEC.

This data has been used to uncover new oil reserves where earlier exploration proved unsuccessful and to optimise field development in areas with reservoir complexities.

EXPEC also introduced horizontal well drilling technology to Saudi Aramco in 1991, allowing significantly more petroleum to be produced per well, both onshore and offshore, than from conventional vertical drilling techniques.