Transmission of data and voice over OTN ensures smooth pipeline operations

Transmission of data and voice over OTN ensures smooth pipeline operations

At Saudi Aramco's new gas processing and transportation activities in the Eastern Province of Saudi Arabia, pipelines interconnect more than 100 gas wells through remote head ends and a central manifold, responsible for bringing the gas back to the Hawiyah Gas Plant for further processing.

For all its communications along the pipelines, between the gas wells, the central manifold, the plant and the central control room, Saudi Aramco is using Siemens Atea's Open Transport Network (OTN) system for transmission of voice and data.

The system was selected because of its reliability, flexibility, low cost of ownership and its ease of use and system manageability.

The OTN communication network spans a distance of more than 400 km, covering the Shedgum, Hawiyah and Haradh areas, using 1310/1550 nm fiber optic technology, with hub distances of more than 60 km.

OTN nodes, located at the well sites, the manifold and the gas plant, are making the following communication services available:

Besides supporting all these applications, a major requirement for the transmission system is reliability: if a well station drops out on the transmission path (for example, due to a power failure), it may not affect the operation of the remainder of the system. OTN, with its unique self-healing capabilities, matches this requirement perfectly.

OTN was also able to meet the specific requirements as to environmental robustness. The OTN nodes are built into passive cooled enclosures, allowing the system to operate at temperatures of 55¡C (131 ¡F) and above.

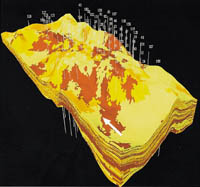

The entire OTN network can be managed remotely from one central location. A network operator located in headquarters is able to visualise the entire network. Configuration changes are easily made via the Windows GUI of the OMS (OTN Management System). Alarms are indicated in real time on the screen.

OTN is marketed worldwide towards large private customers such as oil and gas companies, railway organisations, utilities, etc.

In the Middle East, several OTN systems have been installed including the Riyadh Water Pipeline C (KSA), the Al Samra Waste Water Pipeline (Jordan) and the Ras Laffan Liquefied Natural Gas (RasGas) plant in Qatar.