State-of-the-art production and R&D facilities at Sigma Paints Dammam

State-of-the-art production and R&D facilities at Sigma Paints Dammam

To Saudi Aramco, a Regional Maintenance Program for all its gas oil separator plants (GOSP) pressure vessels is a critical priority.

Taking the vessels out of service for inspection and subsequent refurbishment results in a very significant loss of revenue.

Out-of-service losses are counted in millions of dollars. Therefore, a reduction in downtime would dramatically cut the loss of revenue during these vital maintenance periods.

The single most time-consuming element of pressure vessel maintenance is re-lining. Traditionally a three-coat system is used that requires three days to cure and inspect prior to immersion.

Responding to this situation, the coatings unit of Saudi Aramco's Consulting Services department embarked on a technical evaluation of protective coatings that could handle the severe service conditions and reduce the out-of-service interval.

Once this had been brought to Sigma's attention, their technical sales department suggested a product that considerably reduced the period needed for coatings application and the time to immersion.

The coating selected was Sigma's 7453 Novaguard, a highly successful and well established 100 per cent solids, solvent-free, phenolic epoxy tank lining that can be applied up to 600 microns in one coat.

Tests carried out in independent laboratories and by Saudi Aramco had indicated that 7453 Novaguard would be suitable for this proposed service.

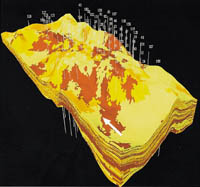

In conjunction with Saudi Aramco's Consulting Services Department and, in particular, its Coatings Unit, and the Test & Inspection department, a two year evaluation and field test programme was devised.

Initiation of the programme was rapidly undertaken. After thorough laboratory evaluation, a production vessel was coated and put back into service.

After a pre-determined period of time, the vessel was emptied, the coating was inspected and the results evaluated. It was found that the coating had performed well and was suitable for continued use.

Again, because the tank was easier to clean, the vessels was returned to service in less time than with normal solvented coatings.

7453 Sigma Novaguard is an advanced 100 per cent solids coating which means that a high build single coat can be applied without any possibility of solvent entrapment. Early corrosion sites such as sharp edges on tank internals are eliminated.

Corrosion and chemical resistance is excellent, as is resistance to cathodic disbondment where cathodic protection is used as a secondary protection system.

Easy cleaning makes inspection quicker and the light colour makes it easier. Added to these general benefits, 7453 Novaguard saved significant time-out-of service revenue losses for Saudi Aramco.

Sigma is a major player in supplying marine paints, protective coatings and decorative paints, according to company official Soliman Al Obedallah.