Bauer's SNG 3 ... used for high pressure systems

Bauer's SNG 3 ... used for high pressure systems

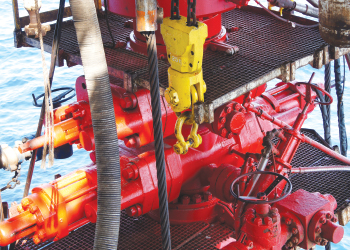

Bauer Kompressoren says its versatile stationary nitrogen generation system, SNG 3, can be used for surface blowout preventers (BOPs) used in subsea applications.

SNG 3 is the company’s stationary on-demand system for high pressure applications up to 6000 PSIG

According to a company spokesman, nitrogen is a dry, inert gas used in a variety of applications, such as vessel inerting (to reduce explosion hazards), instrument air for pneumatic actuation, modified atmosphere packaging, plastic injection molding, process gas and any other application, which requires a high-purity inert gas.

He says with thousands of units in operation worldwide, Bauer nitrogen systems provide a hassle-free, cost effective onsite-on-demand nitrogen generation solution as an alternative to expensive merchant gas.

The SNG 3 is a complete integrated system dedicated to BOP accumulators. This helps create redundancy, minimises exposure, and increases safety.

Offering point-of-use uninterrupted nitrogen generation, the system provides an alternative to external sources of nitrogen by eliminating potential supply chain interruptions and the logistical hassles associated with merchant gas. Thus it says on manpower and costs.

Also the SNG 3’s fail-safe automatic operation maintains consistent BOP accumulator pressures at all times.

The SNG 3 has robust design as is the case with all Bauer on-demand nitrogen systems, which are designed to operate continuously in all manner of severe ambient conditions indoors or outdoors.

All Bauer systems are designed and manufactured to provide Bauer’s legendary reliability and performance with lowest overall lifecycle cost. In addition, every system is backed by Bauer’s two-year, all-inclusive warranty and lifetime support.

Furthermore, customers can keep track of the system via mobile app. Bauer Connect is an app-based IOT solution, which allows customers to remotely monitor the performance as well as control the entire system through any wireless mobile device or computer anywhere, any time.