Quest Integrity, a leader in asset integrity and reliability management segments, successfully performed a high-resolution ultrasonic in-line inspection on two 8-inch diameter rigid risers for a major operator in the Gulf of Mexico.

The solutions offered was an easy-to-use, low-risk untethered one utilising the company’s InVista subsea inspection tool.

The task was part of the operator’s life extension process. It had actively searched for a commercially available solution that could inspect the risers and accurately detect damage while avoiding the operational difficulties that arose with prior inspection providers.

The inspections were required to detect and quantify remaining wall thickness, internal and external metal loss, and deformations to support remaining life calculations of both 8-inch risers.

Early on a performance qualification test was successfully completed at Quest Integrity’s purpose-built test loop to ensure valid data acquisition and minimise project risk offshore.

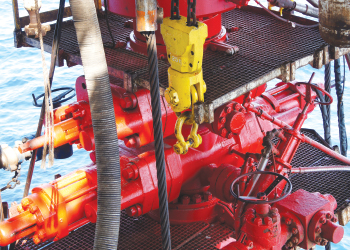

Mobilising a two-man team offshore, the InVista subsea inspection tool was configured for a bi-directional run, being launched topside from a standard short barrel launcher at the sub cellar.

The tool was propelled in diesel at 23 deg C at a rate of 203 gpm to achieve an approximate scan rate of 0.26 m per second. The tool navigated each riser a total of three times, acquiring valid data for a total of 233 m in each direction before being received back at the sub cellar.

Using the data, initial field analysis was then performed on the platform. The InVista subsea inspection tool provided 100 per cent circumferential and axial inspection coverage of each riser. Inspection of both risers was completed in three shifts.

Following field inspection data verification, Quest Integrity personnel returned to the office to analyse and assess the fitness-for-service of the risers based on the inspection data obtained. Repeat inspections to monitor corrosion growth rates were recommended as part of a comprehensive integrity management programme.

Quest Integrity’s InVista subsea technology is bi-directional, untethered, compact and lightweight (approximately 18 kg), which can free flow through 1D bends.