Jasvi ... leading the pack in providing the broadest range of chemistry insights

Jasvi ... leading the pack in providing the broadest range of chemistry insights

OLI Systems’ technologies encompass increased automation with planned enhancements to deliver client-centric software and services-based solutions that enhance operations efficiency and sustainability, and lower costs, Dr Samir Ujam and Saher Jasvi, tell OGN

In the upstream oil and gas sector, a major dilemma is finding ways to streamline production and increase yield while reducing the cost of operations, lowering emissions and enhancing sustainability. Exorbitant amounts of money and manpower are required to design and build facilities, manage materials and equipment, extract resources, and cost-effectively dispose of water while minimising damage to the environment.

|

|

Ujam... leading the pack in providing the broadest range of chemistry insights |

'Oil and gas wells can produce on average 10 times more water than oil or gas (with up to 100 times in exceptional situations), and this water is often saline and unsuitable for surface disposal. As a result, common disposal expenses include permits, separation facilities, pumps, additional pipelines, injection wells, and more. Producing this water can also lead to costly and sometimes catastrophic corrosion, solids buildup (fouling or scaling), emulsion, and reservoir souring problems,' say Dr Samir Ujam, Global Director of Business Development (EMEA), and Saher Jasvi, Senior Solution Consultant, at OLI Systems.

OVERCOMING CHALLENGES WITH WATER CHEMISTRY INSIGHTS

To operate as effectively, sustainably and economically as possible, oil and gas companies must be able to predict when and where problems will occur as well as optimise the use of materials and resources to drive profit margins.

For 50 years, OLI Systems has been leading the industry with water chemistry-based process modeling solutions to enhance efficiency, sustainability and reliability of upstream oil and gas production.

These solutions, which include software and services, help companies design water handling and disposal facilities, simulate production and processing, calculate the likelihood of corrosion or scaling, develop integrity operating windows and enhance asset reliability. They also help to identify and eliminate toxic contaminants in produced water and enhance the ability to effectively capture, store and transport CO2.

Today’s companies face three main challenges - optimal product design, enhancing operations efficiency and reliability, and sustainable water treatment - that are compelling them to invest in the latest technology innovations to evolve their upstream procedures.

Balancing the cost of production with sustainable, product yield is critical to attractive economics, competitive differentiation and regulatory compliance.

OLI Systems utilises comprehensive water chemistry analysis expertise to create modeling tools and capabilities that improve process design and accurately predict operational risk and enhance sustainability which empowers oil and gas producers to make these types of tradeoffs in an optimal manner.

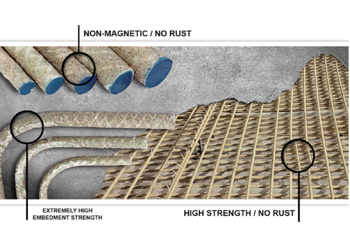

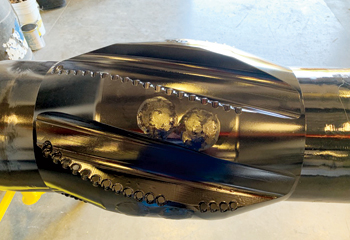

Another major challenge is mitigating scaling and corrosion to enhancing operations efficiency and reliability.

When hydrocarbons are produced, salt-rich water in the same process can cause a number of issues. One of the most common issues is fouling in which, over time, mineral scale buildup chokes off tubing.

As water clogs or corrodes pipelines, companies are forced to pause operations, pull up pipelines, install new pipes, and then resume operations. This cuts off all revenue for an expensive and time-consuming fix with costly materials that increases operational costs and reduces profitability.

The prescriptive approach is to utilise scaling and corrosion modeling to avoid this situation altogether.

OLI Systems’ water chemistry simulation and modeling tools allow companies to predict if they have a corrosive environment, by pinpointing how and why a problem will occur and how and where to treat it.

By uncovering these insights, OLI Systems creates a personalised treatment option to help companies prevent issues and achieve optimal production. OLI Systems’ cutting-edge software tools and industry-leading consulting services, provide state-of-the-art process simulation solutions which deliver key capabilities like mineral scale and corrosion prediction, prevention, and control.

A third challenge is managing the vast amounts of water generated by upstream oil and gas operations. Because this water isn’t environment-friendly, companies must find ways to evaporate it to salts, reinject it, or treat it - all of which require time, money, and resources.

OLI Systems’ process simulation solutions assist companies in handling their discharge water. This critical technology determines the most cost-effective, sustainable and efficient way to process water: Should it be treated to remove solids? Is it too saline to be disposed of in surface waterways? Can it be injected back into the well? Will it damage operating equipment? Solving these complex questions is the difference between a successful upstream operation and one that loses time and revenue and introduces toxic elements into the environment.

As companies seek new sources of hydrocarbon, they will continuously encounter more unique and complex geochemical environments.

OLI Systems’ prediction chemistry is unlike any other tool, with the ability to identify critical properties of the most extreme and remote environments to guide design, construction, and implementation.

The development of high-pressure, high-temperature (HPHT) chemistry has dramatically extended simulation capabilities to predict the formation of mineral scale – PbS, ZnS, CaCO3, and others – beyond the scope of other technologies.

In addition to sophisticated models, software, and profound chemistry expertise, HPHT electrolyte thermodynamics is setting OLI Systems apart and equipping oil and gas companies for not just for today but also the future. Clients can choose to either license an OLI software tool or engage the OLI team as trusted consultants to address their unique water chemistry challenges.

TRANSFORM WATER CHEMISTRY ANALYSIS

OLI Systems’ solutions enable clients to visualise, predict, and solve the most demanding and costly challenges with water chemistry simulation software that delivers highly detailed, accurate insights to optimise operations and reduce risk while enhancing sustainability.

With a combination of rigorous thermodynamic models, software, and an extensive database, OLI Systems provides comprehensive water chemistry solutions through predictive modeling over a broad range of temperatures and pressures using unique chemistries - more accurate and rigorous compared to other alternatives.

The latest chemistry and software innovations in the new OLI Platform V11 significantly increase asset reliability, operational efficiency, and environmental sustainability by accurately predicting process conditions, like scaling, corrosion, and containment of toxic contaminants.

OLI’s cutting edge clean water, air and environmental simulation capabilities now enables management of mercury-based contaminants. New CO2 transportation chemistries enable the prediction of nitric and sulfuric acid corrosion on carbon steel, allowing for accurate risk assessments in pipelines that makes CO2 transportation more efficient.

PROPEL DIGITAL TRANSFORMATION

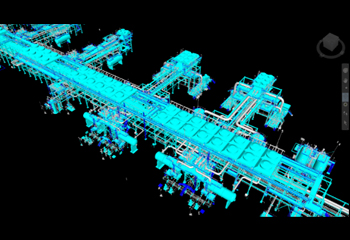

OLI Systems has taken a major step to enable operations excellence by expanding beyond off-line modeling with the new OLI Cloud Platform.

The new OLI Cloud APIs provide automated cloud access to the OLI Engine for custom electrolyte applications in a client’s preferred user interface. The new Cloud App Builder that delivers simple, web-enabled, capability, to develop and publish simple Cloud Apps, democratises electrolyte modeling by allowing operations teams to leverage chemistry insights to improve operations performance. The new OLI Optimizer add-on for OLI Flowsheet: ESP calibrates OLI predictions for specific assets with optimisation algorithms based on operations constraints.

THE FUTURE OF INNOVATION

When it comes to modeling and simulation capabilities, OLI Systems is leading the pack in providing the broadest range of chemistry insights.

OLI Systems’ unmatched approach to electrolyte chemistry along with sophisticated software tools are enhancing process design, analysis and operations with automated insights. So, when customers encounter a chemistry challenge, OLI Systems solutions can uncover the answer with the most advanced, thorough, and accurate modeling.

OLI Systems is actively developing chemistry technologies with increased automation and an ever-evolving database with planned enhancements for scale inhibition, corrosion prediction, water analysis interpretation, and other critical tasks to deliver client-centric software and services-based solutions that enhance operations efficiency and sustainability, and lower costs.

To learn more about how OLI Systems’ solutions can transform operations, write to sales@olisystems.com or visit https://www.olisystems.com/blog/categories/oil-gas.