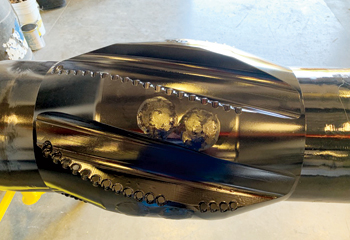

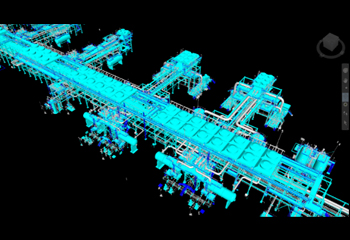

One of the vessels delivered to HSM

One of the vessels delivered to HSM

The four newbuilds have new specifications that do not exist in the market and, therefore, selecting the right partner for this project was crucial, says Al Saeed, Managing Director, HSM

High Seas Marine Industrial Services (HSM), a Saudi-based offshore oil and gas service provider and a registered vendor for Aramco, wanted crew boats, but not just any ordinary models; their design specifications were unlike existing market requirements.

After looking around for reliable companies that could do the job to perfection without compromising on quality, they gave the task to Grandweld Shipyards, a fully integrated shipyard that offers shipbuilding, ship repair, and engineering solutions to the offshore and marine industry around the world.

It took Grandweld 14 months to accomplish the project and deliver four GrandMax Crewboats to HSM, despite the challenges posed by the Covid-19 pandemic. The official delivery ceremony took place at Grandweld’s headquarters at Dubai Maritime City (DMC).

Commenting on the achievement, Eng Ibrahim Al Saeed, Managing Director, HSM, said: "The four newbuilds have new specifications that do not exist in the market. Hence, selecting the right partner for this project was crucial. We were certain that a reliable shipyard like Grandweld would be apt to design and build the required vessels as per the new requirements without any hassle.

He added: "Since we are working with Saudi Aramco, the onus was on us to deliver the best quality to satisfy our client. The support we received from the Grandweld team, especially Eng Abki, despite the global pandemic, helped us complete the project with the best possible quality and as per the decided timeframe."

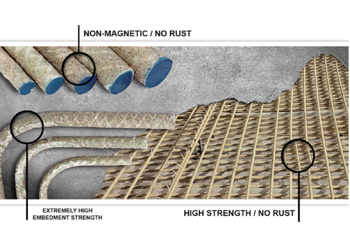

Al Saeed further said: "Usually crew boats are about speed, but apart from speed above 30 knots, other requirements from our end-user included comfort for the crew and high stability. Additionally, the boats are designed to operate under and withstand tough rough weather conditions. So, they are heavier, have a deeper draft and are equipped with extra reserve power. To attain this, we had to achieve speed at 85 per cent maximum continuous rating (MCR) not at 100 per cent MCR. This will ensure that throughout the years the vessel will continue to perform in accordance with the current requirement with reserve."

Backed by years of market expertise, Grandweld showcased its technical expertise and progressive approach with the new vessels.

The shipyard tackled numerous design challenges such as the use of a different kind of block, larger beam and deck space, more depth, higher number of engines with an added fourth engine that will give the vessel speed and extra reserve power to help it perform to the optimum for its lifetime.

Eng Jamal Abki, General Manager of Grandweld Shipyards, said: "Though this is High Seas’ first project with Grandweld, we have had a long-standing professional relationship. However, multiple factors prompted our collaboration for this project. Their decision was driven by our technical capabilities, the reliability of the yard and also the pricing."

He said: "We are proud to have won their confidence and delivered as per our promise. We supported the HSM team with technical insights even before the project was awarded to us and this boosted their confidence in the competencies of the shipyard and led to a successful collaboration throughout the whole process, starting from design to delivery."