Cameron ... supporting Aramco with critical safety equipment

Cameron ... supporting Aramco with critical safety equipment

Local assembly and complete industrial solutions through Sherbiny enhances MSA’s ability to serve region’s customers with faster delivery times, while also strengthening technical support capacity, Ian Cameron of MSA tells OGN

MSA Safety and its long-time local partner in Saudi Arabia, Mohammed Hassan Sherbiny for Commerce (Sherbiny), are both long established suppliers to Saudi Aramco for fixed flame and gas detection products and systems.

Both companies have supported many of Aramco’s large oil and gas projects over the years with the supply of this critical safety equipment.

'Recently, Sherbiny and MSA began to assemble the General Monitors S5000 fixed gas monitor in Saudi Arabia. This new partnership is another step towards supporting Saudi Arabia’s Vision 2030 and providing new employment opportunities for citizens in support of the local economy,' Ian Cameron, MSA Marketing Manager – Fixed Gas & Flame Detection for the Middle East, Africa, India, Russia and Caspian Region.

|

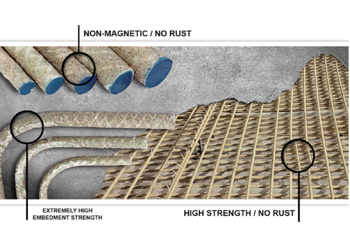

The S5000 gas monitor offers higher levels of overall performance, |

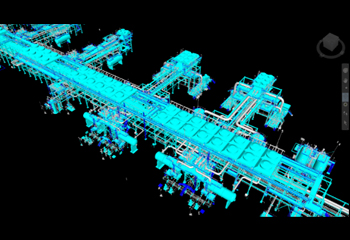

Sherbiny, a leading provider of premium oil and gas equipment and solutions in Saudi Arabia, assembles MSA products locally at its new facility in Al-Khobar.

By providing local assembly capabilities along with complete industrial solutions and engineering and technical services through Sherbiny, this partnership enhances MSA’s ability to serve customers in the region with faster delivery times, while also strengthening MSA’s technical support capacity and customer service.

With the launch of the General Monitors S5000 gas monitor and XCell® sensors, it demonstrates MSA’s commitment to enhancing the level of safety for workers who may be exposed to harmful gases, including hydrogen sulphide (H2S) and carbon monoxide (CO). At the same time, the improved performance and self-diagnostics of the new sensor technology also helps to lower the total cost of ownership for the user.

• The technology behind the new sensors: MSA’s new advanced sensor technology is called TruCal® and offers many benefits to the user and their associates working in hazardous areas, including enhanced levels of safety; multiple sensor status checks per day; self-calibrations in the event of sensor drift due to changes in the environment; and automatic monitoring on the sensor inlet for blockages. Additional benefits include extended manual gas calibrations (up to two-years); higher levels of overall performance, with better stability and measurement accuracy; longer sensor life, with new ionic non-consuming electrolyte technology; industry leading three-year sensor warranty; and a longer shelf life (up to 3-years) reducing stocking costs.

|

The S5000 with MSA’s new advanced TruCal sensor technology |

MSA’s revolutionary TruCal technology sets a new standard for performance and reliability and is now assembled locally by Sherbiny in Saudi Arabia.

Today, the best practice for the oil and gas industry is to calibrate gas detectors that use electrochemical cells every 90 days. Such calibrations are necessary to determine whether these traditional electrochemical sensors are still able to detect the target gas or if the sensor’s inlet is blocked. This is only discovered during a manual gas calibration, when gas is applied to the sensor.

However, between these manual calibrations, the electrochemical could be unable to detect gas at any time. This is the fundamental reason why frequent, labour-intensive, expensive servicing was required for these types of sensors. TruCal technology reduces this uncertainty as it performs a sensor self-check four times a day.

TruCal technology is incorporated in MSA’s patented XCell H2S and CO electrochemical sensors. The Pulse Check within the sensor provides a reliable sensor interrogation method that identifies and corrects for changes in output sensitivity (sensor drift).

The Pulse Check uses MSA’s patented technology to calculate gas response by applying an electronic pulse to the sensor and analysing the response curve of the last manual gas calibration.

Through proprietary algorithms, MSA can quantify positive and negative drift that results in real-time accuracy adjustments (self-calibrations) during the Pulse Check. Users can also rest assured of accurate sensitivity and functionality. This latest technology is referred to as Adaptive Environmental Compensation (AEC) and occurs every six-hours, which allows for manual gas calibrations to be extended up to two-years.

The second part of Trucal is called Diffusion Supervision. In an industry-first, Diffusion Supervision monitors the sensor’s inlet for blockages, which would prevent gas from reaching the electrochemical cell inside. If the inlet of a traditional sensor becomes blocked, the sensor cannot identify this dangerous condition and alert the user. This is one of the reasons why frequent manual gas calibrations are recommended.

• New sensor design: The revolutionary electrochemical sensor design uses a new type of electrolyte, which reacts with the specific target gas. The electrolyte is an ionic liquid with a lower vapour pressure, so it doesn’t evaporate and most importantly is not consumed during the chemical reaction that occurs when the target gas is present. Instead of the one-to two-year sensor life (depending on application and environment) of MSA’s traditional electrochemical sensors, users can now expect a sensor life of up to five years, supported by an industry-leading three-year sensor warranty.

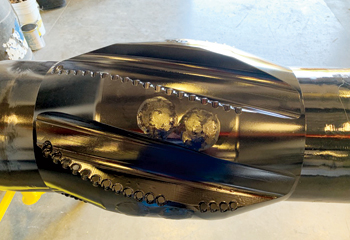

• Rugged and easy to use transmitter: The S5000 stainless steel 316 transmitter design has been enhanced with a touchscreen display for menu access, as well as a brighter display for easy visual status indication. Additionally, the S5000 offers LED indicators for normal operation, fault and alarm indication. An easy retrofit of the detector is possible because it shares the exact mounting footprint as the previous model — the S4000 series — making upgrades quick and easy since the existing installation accessories and cabling can be reused. This also means there is no requirement for hot work.

• User-friendly interface: MSA also introduced Bluetooth communication for point gas monitors for the first time. Through the MSA Connect app, the transmitter’s menu can be accessed over encrypted and secure wireless communication. This allows for faster initial device configuration, saving valuable time and also for remotely accessing the transmitter when located in inaccessible locations. Various XCell sensors can also be fitted with the new X/S5000 CalGard Remote Calibration Adapter. This allows for the sensor to be remotely calibrated and not just a simple bump test like a gassing adapter permits. Remote calibrations can be performed safety from up to 30 metres from the sensor.

• Do more with less, utilising the new dual sensor capability: The S5000’s dual sensing technology doubles the sensing power while reducing the capex of the transmitters and also reducing the installation cost as less cabling, cable trays, junction boxes and other installation accessories are required. One or both of the sensors can be remotely mounted up to 100 metres from the transmitter, giving greater flexibility to the user by positing the sensor exactly where they are required, while still being able to easily access the transmitter.

MSA’s TruCal technology determines if a sensor is installed, operating within its predetermined sensitivity limits, and is corrected to account for any drift since the last pulse check event and checks whether the inlet is unblocked.

The six actions that TruCal enables include:

• Validating that the sensor is operating normally.

• Compensating for sensitivity drift due to changing environmental conditions.

• Recommending when a full manual gas calibration should be performed.

• Warning when a sensor needs to be replaced in the near future, by indicating the sensor life as 'good' or 'fair'.

• Checking the inlet of the sensor is not blocked, preventing gas detection.

• Alerting the end user if the device is no longer able to monitor the area, by initiating a fault signal.