Thore ... leading Sulzer Chemtech TFS as the specialist revamp service provider across all plants

Thore ... leading Sulzer Chemtech TFS as the specialist revamp service provider across all plants

Backed by a global network of tower field specialists, the company leveraged 300 people for the project, making it possible to complete the revamp in only 24 days, Vijay Thore from Sulzer Chemtech tells OGN

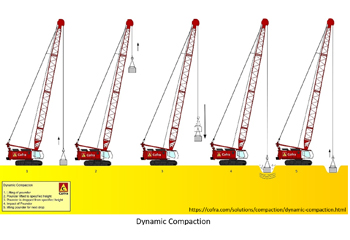

Refineries need to maximise process uptime and performance to reliably support market demand. This means that when equipment optimisation projects are required, they need to be completed while adhering to tight maintenance and repair schedules.

Responsive tower field service specialists are key to succeeding in this strategy. When a world-leading integrated energy and chemicals company needed to push forward the revamp of multiple columns at its refinery in Saudi Arabia, Sulzer Chemtech completed the project in a record time of 24 days.

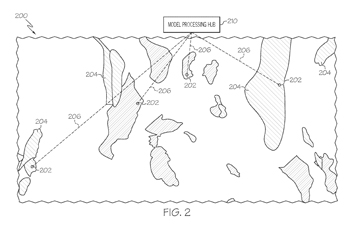

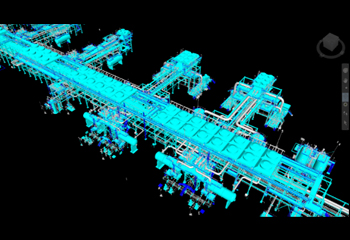

The oil major runs one of the oldest Saudi refineries on the Arabian Gulf coast. This is an essential site that supports the needs of several countries in the region. For that reason, it is fundamental for the refinery to run at peak performance, avoiding bottlenecks or extended shutdowns.

|

In order to ensure availability and productivity, it is sometimes necessary to adjust the facility’s maintenance schedules to bring forward equipment improvements. This was the case for four columns and one flare knockout (KO) drum in one of its plants within the refinery.

These pieces of equipment were underperforming and, since they play a critical role at the site, their revamp had to be prioritised.

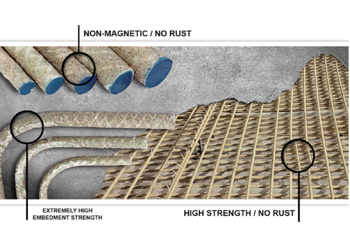

To quickly install new components to improve the capabilities of the five units, the refinery contacted Sulzer Chemtech, a leader in separation and mixing technology, and its Tower Field Service (TFS) team. The company was selected as it was able to complete the revamp in less than a month, the lowest quoted timeframe for the project.

Sulzer Chemtech has a proven track record of delivering highly effective upgrades on separation units in a wide range of applications.

Since the last decade, Sulzer Chemtech TFS has established itself as the specialist revamp service provider across all plants, with expertise in and knowhow of a wide range of equipment.

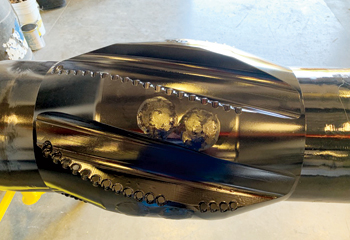

Just before the start of the project, an inspection revealed additional damage in the columns that was needed to be addressed. In particular, the emergency repair of three beds in the vacuum distillation unit (VDU) was required, considerably increasing the scope of work. In effect, new components had to be manufactured and installed.

Thanks to its global network of tower field specialists, Sulzer Chemtech was able to overcome this challenge without impacting the overall project timeline. The company was able to quickly mobilise additional staff, leveraging approximately 300 people for this project. By doing so, it was possible to complete the revamp in only 24 days.

After the columns had been revamped, the plant was able to restart its operations at full capacity, eliminating the initial bottlenecks.

Extremely satisfied with process enhancements and the round-the-clock support received from Sulzer Chemtech, the refinery issued a certificate of appreciation recognising the successful completion and execution of the critical project.

Vijay Thore, Head of Operations– Tower Field Services Middle East at Sulzer Chemtech, concludes: "We are delighted with the feedback received. Helping our customers improve their operations is extremely important to us. Our global presence of service and manufacturing centres is key to our success in addressing even the most ambitious projects and overcoming the unexpected. We look forward to supporting our customers in the future to and further enhancing its competitiveness."

-is-one-of-the-world.jpg)

-(4)-caption-in-text.jpg)