The RoTechBooster ... abundant, reliable, and consistent seal gas flow

The RoTechBooster ... abundant, reliable, and consistent seal gas flow

The company is in final discussions with its international partners for localisation, which is in line with the Kingdom’s Vision 2030 and the company strategy to expand and diversify its portfolio

When a major natural gas provider in North America started experiencing frequent dry gas seal failures on one of its pipeline compressors, it turned to EagleBurgmann’s compressor sealing experts for a solution. There was interruption in gas transportation, causing challenges to meet customer demands, along with unplanned and costly maintenance.

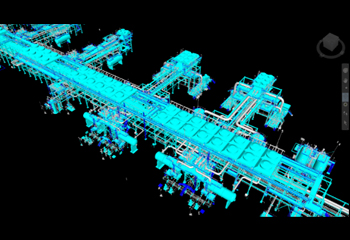

The concerned pipeline company builds and operates, safe and reliable energy infrastructure, which includes a 93,300-km natural gas pipeline network. This network provides more than 25 per cent of the clean-burning natural gas consumed daily across North America for heating homes, fueling industries, and generating power.

A compressor in the network was striving to meet the required uptime. As centrifugal process gas compressors are vital components in the energy supply chain, they must fulfill very high availability, reliability, and safety standards. Unexpected compressor downtime severely impacts the ability to meet customer’s needs.

Several seal failures had led to a gas supply interruption, and this was proving very costly due to seal repairs, manpower and consequential compressor damages.

The situation was assessed and the pipeline company identified two concerns: Firstly, seal gas supply loss during pressurisation and standby operation; and secondly, a high contamination content in the seal gas, which was overburdening the existing seal gas filters.

EagleBurgmann and the company jointly researched and investigated the causes, and decided to implement the RoTechBooster, an electrically driven seal gas booster to remedy the situation.

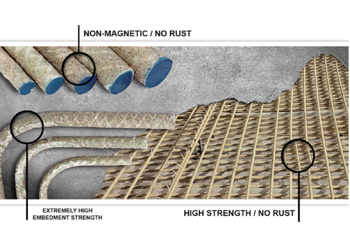

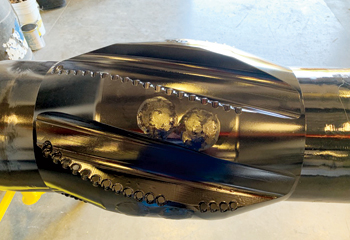

The RoTechBooster is a proven seal gas booster that keeps dry gas seals reliably clean not only during standby conditions, but any time insufficient seal gas flow occurs. The rotating design includes the ability to maintain an unlimited pressurized hold.

A suitable RoTechBooster model was selected according to the prevailing operating conditions. The high seal gas contaminant content was managed with a coalescer filter with the additional of a cyclone to remove most of the debris and liquids. This allowed the coalescing filter to manage the remaining fine debris and aerosols more effectively.

A skid was designed with these requirements in mind for delivering the most effective solution. As the seal gas system incorporated fixed orifices for controlling seal gas flow during normal operation, they produced too much restriction for the RoTechBooster to deliver sufficient seal gas flow when operating.

The RoTechBooster system was designed to bypass these orifices to ensure sufficient seal gas supply (6 AM3/H) to the seals. The system was designed for the required conditions and manufactured by EagleBurgmann.

The RoTechBooster with the additional filtration was installed in June 2019 at the site. Since there was no major restriction in the seal flow path (fixed orifices bypassed) when the RoTechBooster was operating, the flow produced was 10 actual cubic metre per hour (Am3/h). The flow was manageable by the filters and the additional consistent flow provided increased assurance the dry gas seals weren’t exposed to dirty process gas.

RESULT

After two years of operation, numerous stops and starts and over 5,000 RoTechBooster operating hours, there has been no change in seal leakage, indicating the dry gas seals are contamination free.

The seal gas filter inspection verified they were in excellent condition, which is a big difference from inspections previous to the RoTechBooster skid installation. All pipeline contaminants were effectively being removed with the cyclone added to the filtration system.

According to the station operator: "Over the past year the booster pump at this site has been functioning as well as I could have hoped. The pump has just over 2,500 hours runtime with zero issues. Best thing of all, no issues with the dry gas seals."

The RoTechBooster ensures abundant, reliable, and consistent seal gas flow, through fluctuating operating conditions; thus, clean and dry gas is supplied to the gas seal in every situation. Some advantages offered by the system include:

• Simple to set-up, easy to operate.

• High reliability and availability.

• Unlimited continuous operation.

• Avoid seal failures.

• Low maintenance costs.

• Energy efficient.

• Eliminates the concern of unreliable external seal gas source.