The BM series is synonymous with reliability

The BM series is synonymous with reliability

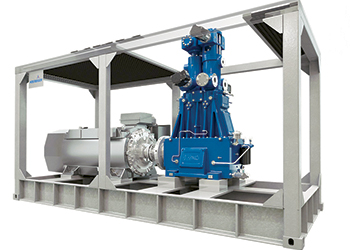

Bauer’s new BM Medium Pressure Series deliver pressures of up to 40 bar for the two-stage models, and 100 bar for the three-stage models, making the devices optimum for typical applications in the energy sector, offshore applications, industrial applications, shipbuilding industry and shipping, marine, and defence industry.

A suite of optional features is available including compressor control unit, pressure and temperature monitoring system for all compressor stages, and air and gas purification systems. This allows bespoke configurations to be tailored to customers’ individual needs.

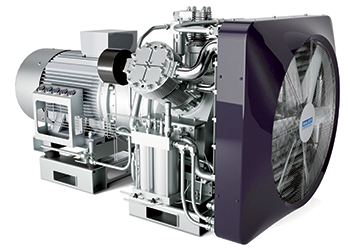

The BM-series has two or three compressor stages. An integrated oil pump provides forced lubrication to all essential components of the compressor under the most severe operating conditions.

Air-cooled design with a large cooling fan provides optimal cooling across all cylinders even at high ambient temperatures. All compression stages are protected with integrated inter-stage safety valves.

Like all Bauer systems, the BM series is synonymous with ultimate ruggedness and reliability in even the toughest environments, making these compressors the ideal choice for difficult application scenarios.

The BM Series’ extensive features and capabilities open up a virtually unlimited range of applications for their users.

With compact footprint, low centre of gravity and ability to operate at extreme angles up to 30 degrees, they are perfect for marine and offshore scenarios.

DNV approval is naturally possible, and their extra-low operating costs, with minimum oil consumption and long maintenance cycles, are particularly attractive to compressor operators.

Low oil consumption, long maintenance intervals and transparent maintenance kits also reduce the total cost of ownership (TCO).

In additional equipment options, the BM series can be fitted with the powerful compressor control C-Control+.

Coming with a 4.3-inch touch screen colour display, the control system enables monitoring of pressure and temperature, recording of load changes in the final separator, maintenance management, direction of rotation monitoring and operating hours display.

With this additional module, the pressures and temperatures of all compressor stages are monitored.

If the set limit values are exceeded or undershot, the system is automatically switched, and the indication shown on the display.