Smart-LOC ... a high integrity modular concept for pneumatic actuator control assemblies

Smart-LOC ... a high integrity modular concept for pneumatic actuator control assemblies

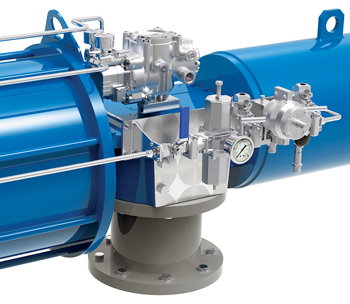

ROTORK Midland has introduced Smart-LOC, a new high integrity modular concept for pneumatic actuator control assemblies.

Constructed in 316L stainless steel, the Smart-LOC system is particularly suitable for the control and sequencing of process valve actuators in oil and gas applications, says a company release.

Compared to traditional fabricated panel mounted assemblies Smart-LOC offers a lighter, stronger and more compact alternative, together with significant capital and operating cost savings.

Complex, labour intensive arrangements using panels, pipes and additional fittings are eliminated and replaced with a fully assembled and tested interface block, ready to be fitted directly to the actuator. Delivering best in class flow characteristics, the units will interface with all types of pneumatic actuators.

A range of field proven components – valves (spool, poppet or direct mounting) and filter regulators – connected in series on the interface, are tailored to meet the requirements of individual projects, ranging from standard shut-off circuits to intricate control circuits.

The unique Smart-LOC clamping system for individual components incorporates static O-rings for higher integrity and long term reliability. No design work is required from the contractor and all components are kept in stock, resulting in very short lead times.

With Atex approval, Smart-LOC components are suitable for hazardous areas and industrial use. The integral Smart-LOC clamping system also simplifies field maintenance, enabling individual components to be simply and swiftly unclamped and replaced.

Smart-LOC is designed with the benefit of more than 50 years’ experience in the manufacture of stainless steel pneumatic components, during which time Rotork Midland has developed a range of field proven specialist products that are renowned for their performance and reliability.