The DCM method allows for testing while both sides of the breaker is closed

The DCM method allows for testing while both sides of the breaker is closed

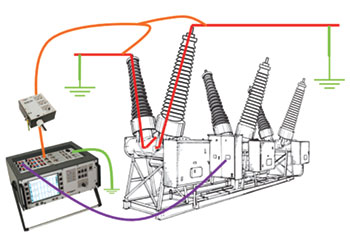

Timing tests on high voltage (HV) circuit breakers play a crucial role in ensuring the reliability and effectiveness of electrical networks.

It is, therefore, essential that advanced testing equipment is used for conducting accurate tests, especially in scenarios where both sides of the circuit breaker are grounded.

This article explores how the dynamic capacitance measurement (DCM) functionality in Megger TM1700, TM1800, and EGIL200 test sets can be utilised to conduct precise timing tests in dual grounding situations.

IMPORTANCE OF GROUNDING BOTH SIDES OF HV BREAKER

Conducting timing tests on HV circuit breakers is considered dangerous in energised substations due to many factors.

These include induced currents from nearby conductors transferring load current, capacitive coupled currents from nearby energised installation (for example, overhead lines) or accidental re-energisation.

The consequence could include seriously dangerous situations like electrocution, burns from arching, secondary injury like tumbling down from ladder due to electrical shock, and even damage to the test equipment since no test equipment is design to handle these high leakage or induced voltages.

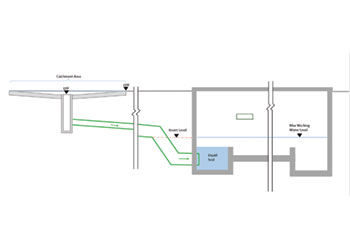

To ensure safety, the test should be conducted in a dual ground arrangement.

However, the difficulty is that the conventional way of conducting the test (utilising continuity to measure the open and close times) won’t work because there will always be the ground shorting both sides.

So the breaker will always be shown in a closed position, and this makes the test invalid or not possible.

The solution then is to conduct the timing test with an alternative method to the continuity (conventional) method.

DYNAMIC CAPACITANCE MEASUREMENT METHOD

In 2006, Megger came up with a method that can work when both sides of the breaker are closed.

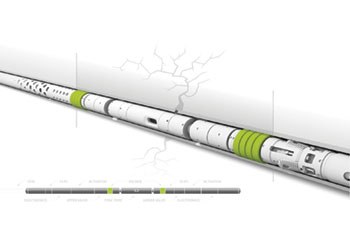

This method called Dynamic Capacitance Measurement (DCM) detects if the breaker is open or closed by simply looking at the breaker circuit as a variable capacitance.

This is how the DCM performs timing measurements:

• A resonant circuit applies a sweep frequency current signal while the breaker is in closed position.

• The device tunes to the lowest current frequency and locks to that frequency.

• Whenever the circuit breaker changes position, the capacitance of the measured circuit will change thus changing this current at that locked frequency.

• The testing equipment will record the times at which the current changes in the locked frequency as the opening or closing times thus conducting timing test measurement.

• This is all done while both sides of the breaker is grounded thus increasing the safety of the test.

CONCLUSION

The DCM method allows for performing timing tests on high voltage circuit breakers while both sides of the breaker are grounded, thus increasing the safety of the test.

An added benefit is that in some cases, the DCM will make the test easier than conventional method, especially when dealing with generator circuit breakers and transformer bays where removing ground links is a cumbersome task.

The same difficulties arise in the case of gas insulated switchgear (GIS) as well.

DCM avoids these difficulties all together hence making the test much easier and time efficient.