Al Khonaini ... carving a niche in Saudi Arabia

Al Khonaini ... carving a niche in Saudi Arabia

The company, established in late 2010 with a total investment in excess of SR660 million ($176 million), has recently received Sour Service approval from Saudi Aramco for manufacture of specialised line pipes

Jubail-based Global Pipe Company (GPC), a specialised manufacturer in the Middle East of thick-walled steel line pipes, remains committed to expanding its presence through the wider GCC.

The company has also found itself particularly well placed to capitalise upon Saudi Aramco’s growing demand for its productive and technical abilities to supply of well casings for upstream development, says Ahmad Hamad Al Khonaini, managing director of GPC.

GPC, established in late 2010 with a total investment in excess of SR660 million ($176 million), has recently received Sour Service approval from Saudi Aramco for manufacture of specialised line pipes. The approval by Saudi Aramco for supply of Sour Service Material is particularly notable given the fact that GPC is comparatively a new player in the domestic pipe manufacturing sector. Importantly, it also means the company now occupies an exclusive market position shared by only a limited number of global producers.

"Around 12 pipe manufacturers worldwide – including GPC – are currently certified by Saudi Aramco for Sour Service Material Longitudinal Welded Pipes and we are diversifying our portfolio by supporting Aramco’s upstream development activities through supply of the well casings used in drilling," says Al Khonaini.

GPC secured a major new supply agreement with Saudi Aramco for the extension of Saudi Arabia’s Master Gas System (MGS) – a country-wide network of pipelines and gas-processing plants initially established in 1970s and expanded upon considerably over the decades to become the facilitator of ethane and LPG production in Saudi Arabia.

GPC has commenced work on the contract, which will entail providing pipeline material for over half the new 1,000-km-long pipeline network that is destined to stretch across the eastern, central and western regions of Saudi Arabia. The Master Gas Project is a challenging project in terms of both quality and quantity. The pipe size required is 56-inch diameter, with wall thickness ranging from 14.25 mm to 25.4 mm, he explains.

The company’s recently concluded Fadhili contract for the delivery of 27 km of pipes provided excellent training for GPC’s Master Gas Endeavour requiring, as it did, production of pipes of the same huge diameter, and of a very similar thickness range.

Above and beyond such fortuitous experience, however, GPC developed an action plan to secure higher output and smooth execution of Saudi Aramco’s mega contract. This action plan has led to investments in improved plate logistics, a new X-ray inspection bunker, increase manpower, and – not the least – a new Manufacturing Execution Software System.

"Last year, GPC concluded supply agreement with Saudi Aramco providing us with clear growth opportunity as well as an excellent point of reference to supply our pipes to Shedgum project – 150 km, east-west gas pipeline connecting the Shedgum gas processing plant with the Yanbu export terminal. GPC supplied a total of 84,000 mt (metric tonnes) of steel pipes made of API 5L X65 PSL2, with diameter of 32 inches (812.2 mm) and wall thickness of 26.97-31.75 mm," Al Khonaini says.

|

GPC secured a major new supply agreement for Saudi Aramco’s Master Gas System |

In another feather in its cap, GPC has also received approval for Well Casing for OCTG (Oil Country Tubular Goods) applications from Aramco. It has also embarked on a new venture to supply value-added services to the local market, he says.

GPC, which is taking part in Adipec 2016 (Stand 13554 Hall 13), intends to target for business some major customers in other GCC countries such as, Abu Dhabi National Oil Company (Adnoc), Kuwait National Petroleum Company (KNPC), Qatar Petroleum and petroleum Development of Oman.

Back home in Saudi Arabia, Al Khonaini says: "We have a plan to expand our mill facility to increase our output to cover the growth demand from the local market. Also, we are planning to install a new pre-bending machine for heavy wall thickness pipes with higher grade material."

The company’s facility features a completely self-contained laboratory for mechanical testing and chemical analysis, as well as non-destructive testing (NDT) facilities, including two ultrasonic testing (UT) machines and four X-ray bunkers. It will

GPC is a Saudi German joint venture company between German specialised Longitudinal Submerged Arc Welded (LSAW) pipes manufacturer Erndtebrucker Eisenwerk (EEW), Saudi Steel Pipe (SSP), Ahmad Hamad Al-Khonaini and Pan Gulf Holding.

"In the last quarter of 2012 we completed the construction of the plant and started tuning the machines, and a trial production took place in first quarter of 2013. In March of that year we completed our first pipe delivery," says Al Khonaini. The company will have a formal inauguration of its new facility on November 6, 2016.

GPC was set up with the purpose of manufacturing thick-walled steel pipes, targeting mainly the Saudi Arabian and GCC markets.

"Our strategic partner EEW is one of the most experienced manufacturers of thick-walled pipe in the world using the very latest equipment and machinery. During the second quarter of 2013, GPC succeeded in gaining approval from the America Petroleum Institute (API) and on November 25, 2013 the company’s pipe mill was awarded official supplier status by Saudi Aramco for non-sour pipes and structural tubular."

At present, GPC will also focus on diversifying its range from low-end to high-end industrial pipe products, in addition to providing value-added services. This is the core of the company’s development strategy and clearly reflected by its new approval for sour service material and its new venture supplying well casings to Saudi Aramco, he says.

The company’s plant is set up on a 120,000 sq m plot, with 57,000 sq m of it being in a covered area incorporating production machinery and equipment. The plant is currently operating on two shifts with more than 400 employees. The annual capacity is 300,000 tonnes.

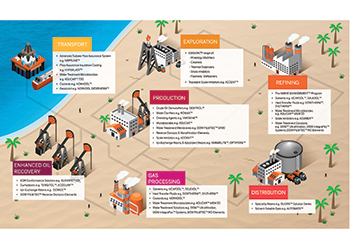

GPC intends to serve the oil and gas sector as well as offshore and structural applications producing longitudinal submerged arc welded (LSAW) pipes, specialising in the production of large-diameter, heavy wall thickness pipes in two main categories. Line pipe with outside diameter from 16 to 62 inches and wall thickness from 8 to 51 mm, and structural tubular with outside diameter up to 200 inches (about 5 m) and wall thickness up to 130 mm.

GPC is committed to fulfilling all of the relevant health, safety and environmental requirements as set out by Royal Commission for Jubail & Yanbu, which sets very high standards in these areas, he says. "Furthermore, as part of the company’s integrated management system (IMS), we adhere to internationally recognised systems and have obtained a number of accreditations in this regard namely ISO 9001for quality management. We have also attained the following API specifications:Q1 for manufacturing in the petroleum and natural gas industry; API 5L for manufacturing welded steel pipes for use in pipeline transportation system; and 2B for fabrication of structural steel pipe suitable for use in construction of welded offshore structures," says Al Khonaini.

He says GPS’s vision is to become the leading manufacturer of heavy wall thickness LSAW pipes in the Middle East and North Africa and to supply superior quality products in compliance with customer specifications and requirement.

"One of our main achievements in recent months has been installation of the Manufacturing Execution Software System to cover all main processes in its operation," he adds.