The SPM EXL Frac Pump

The SPM EXL Frac Pump

Weir engineered the SPM EXL Frac Pump to address major challenges operators currently face: the need for longer pumping hours with extended maintenance cycles and irregular maintenance practices caused by inexperienced field teams

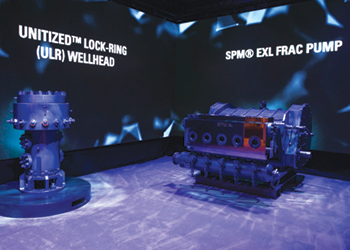

Weir Oil & Gas, a leading upstream provider of pressure pumping and pressure control equipment and services, introduced at OTC 2019 its new SPM EXL Frac Pump – engineered from the ground up to be the most durable, longest-lasting 2500 horsepower pump on the market. With the highest rod load rating in its class at 238,000 pounds, Weir’s SPM EXL Frac Pump is designed to withstand today’s harshest fracking conditions and ease maintenance for operators’ field teams.

Weir engineered the SPM EXL Frac Pump to address major challenges operators currently face: the need for longer pumping hours with extended maintenance cycles and irregular maintenance practices caused by inexperienced field teams struggling to maintain an ever-growing inventory of equipment. To build a pump capable of withstanding the inevitable abuse of today’s operations, Weir examined the most common failure modes of frac pumps and designed targeted engineering solutions to address them. Throughout the development process, Weir applied key learnings garnered from its flagship SPM QEM 3000 pump, resulting in a pump more reliable than any other in its class.

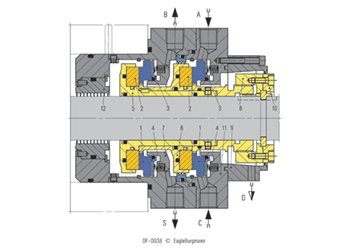

The new pump frame is constructed with an integrated skid designed to reduce vibrations across the frame and increase stiffness, thus reducing stress on the weld. The frame also drastically reduces the number of internal groove welds to reduce cracking. All welds are located on the outside of the frame, making them more accessible.

To address the higher stresses put on the gear system from high torque encountered when operating at high rod loads, Weir completely redesigned the gears and pinions utilising the latest manufacturing techniques to provide greater surface area contact on the bull gears and reduce the risk of stripping them.

Additionally, a key focus of the new pump is to reduce the amount of onsite maintenance required for operators. To accomplish that goal Weir introduced the SPM Everbore, a hardened steel packing bore which eliminates wash boarding and protects against packing bore wash so there is no need to re-sleeve. It is designed to last the entire lifetime of the fluid end and is intended to eliminate maintenance in the red zone.

"This pump is a true testament to how Weir leverages our engineering expertise to offer our customers a pump with the highest rod load rating in its class with unmatched reliability," said Paul Coppinger, President, Weir Oil & Gas. "We are committed to driving towards having zero maintenance in the red zone, and this newly engineered pump represents innovation and progress toward that goal for our customers."

Weir’s new SPM EXL Frac Pump is designed as a drop-in replacement for existing QWS 2500 pumps and other 2500 pumps, eliminating the need for trailer retrofits. The pump also simplifies maintenance and repair with maintenance guides and information printed directly on the fluid end. Training videos will be available end of Q2 2019.

The SPM EXL Frac Pump is supported by Weir Edge Services, Weir’s global service offering. With service and training centers in every US basin and every part of the globe, Weir Edge Services supports operators with a three-pronged approach that includes global access to engineering experts, engineered repairs, highly skilled aftermarket support, and industry-leading digital empowerment tools for Weir and other OEM equipment.

Today’s announcement is part of Weir’s participation in the 2019 Offshore Technology Conference at NRG Park. Throughout the conference, Weir is demonstrating its innovations to improve reliability and efficiency for oil and gas operations in Booth 3438.

Weir Oil & Gas provides superior products and service solutions to make our customers more efficient and lower total cost of ownership.

More customers choose our pressure pumping solutions than any other. We provide well service and stimulation pumps, flow control products, replacement expendable parts and supporting engineered repair services. Weir’s Pressure Control solutions include wellheads, API valves and frac trees, managed pressure drilling equipment including chokes, separators and containment equipment. Globally we deliver engineered mechanical and rotating equipment repairs and upgrades, oilfield and drilling equipment repair and certification, rapid prototyping of spare parts, robust asset management and field engineering services.