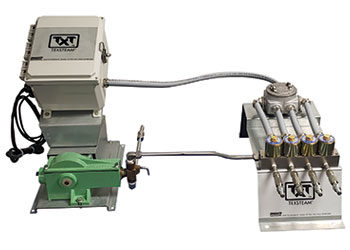

The Texsteam multipoint injection controller

The Texsteam multipoint injection controller

Dresser Natural Gas Solutions (Dresser NGS), a leading provider of measurement, instrumentation and piping solutions to the natural gas distribution and transmissions markets, has launched a multipoint injection controller adjustment for its Texsteam pumps, through its Industrial Products Group (IPG).

Texsteam multipoint injection will be used in oil and gas wellhead chemical injection operations to distribute chemicals from a single chemical injection pump to multiple injection points.

Jeff Raynal, general manager, Dresser NGS IPG, says: "Texsteam multipoint injection offers increased flexibility by enabling users to distribute different flow rates to various end points with one pump head and a simple controller. This lowers capital spend by reducing the amount of equipment required for chemical injection. Instead of needing four pumps for four different wellheads, the operator will now be able to inject four wellheads with just one pump."

The Texsteam multipoint injection system works to a maximum operating pressure of 2,500 psi with the solenoid assembly having only 10 W power consumption.

The electrical junction box is explosion-proof, dust-ignition proof, and raintight certified. The solenoid valves are Class I and II Groups C, D, E, F & G, Division 1 and 2. The multipoint system is used with the Class 1, Div 2 iCIP Solar package.

.jpg)