The sustainable pipeline is part of GRDF's green programme

The sustainable pipeline is part of GRDF's green programme

French gas utility network operator, GRDF, has installed what it says is the fully sustainable gas pipeline.

The pipeline is made from bio-based, certified HDPE supplied by Ineos Olefins & Polymers Europe.

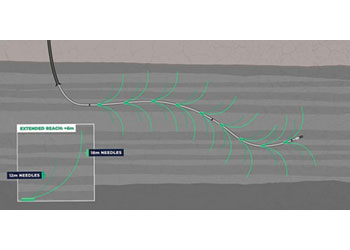

The new pipeline is installed in Clermont Auvergne Métropole, in the French city of Clermont-Ferrand, as part of a GRDF programme to ‘green’ pipelines in parts of the region with a similar commitment to reducing their carbon footprint.

One kilometre of pipeline will be laid across three sites in the Clermont Auvergne Métropole gas network.

It’s made from wood processing residues from the paper industry, which are transformed into tall oil, a bio-naphtha.

The tall oil is turned into bio-ethylene in Ineos Cologne and transported to Ineos’ polymer plant in Lillo, Belgium, where it is used to manufacture bio-based HDPE.

The result is a polymer with a significantly lower carbon footprint than conventional, fossil-based polymers and because of this it has been recognised by the International Sustainability and Carbon Certification (or ISCC), an independent, third-party organisation.

ISCC has certified that the production of the pipes laid by GRDF met ISCC Plus standards by replacing the use of fossil fuel-derived feedstocks to produce the new material.

Importantly the bio-polymer has the same technical characteristics as conventional polymers, enabling a partner like GRDF to meet the highest standards of safety while reducing the environmental impact of networks it operates on behalf of local authorities.

It also creates the potential for the innovation to be repeated for other gas and water pipelines.

All polymers offered by Ineos Olefins & Polymers Europe are also 100 per cent recyclable, alongside the lower carbon footprint associated with the bio-based HDPE.

Alexandre Pierru, GRDF Innovation Project Manager, said: "GRDF has proven that it’s possible to distribute biomethane, a bio-based gas, with bio-based certified polyethylene pipes. It’s thanks to our collaboration with partners such as INEOS who showed a strong will to find solutions to decarbonise the raw material of our pipes."