Kevin Killeen

Kevin Killeen

Compared with traditional flame detection systems, companies have reported significant reductions in false alarms through artificial neural networks, leading to enhanced operational continuity and improved worker safety

In industrial settings where flammable materials are prevalent, flame detection systems play a pivotal role in ensuring safety.

These systems act as an essential component of comprehensive safety programmes, designed to identify the presence of flames early to prevent catastrophic fires and explosions.

However, the challenge of false alarms poses a significant threat to operational efficiency, often leading to unnecessary disruptions and potentially desensitizing personnel to genuine alerts.

As industries strive for enhanced safety, understanding the various flame detection technologies becomes imperative.

Traditional flame detection methods, including infrared (IR) and ultraviolet (UV) sensors, have been widely used to monitor flames. Yet, these systems are not without limitations; they can be susceptible to interference from environmental factors such as sunlight, dust, and smoke, says Kevin Killeen, the Global Product Line Manager for Flame Detection at MSA Safety.

This vulnerability increases the risk of false alarms, making it challenging for operators to differentiate between real threats and benign triggers.

As a result, the need for more advanced, reliable solutions has never been greater in industrial environments.

Recent advancements in technology have led to the development of artificial neural networks (ANNs) as a sophisticated approach to flame detection.

These networks, inspired by the human brain's structure, are designed to learn from vast datasets and improve accuracy in identifying genuine flames while minimizing false alarms.

With industries increasingly adopting these advanced diagnostic tools, the focus now shifts to how ANNs are transforming flame detection systems and enhancing safety across various sectors.

Below are excerpts from the interview:

What is the role of flame detectors in industrial settings and the types of hazards they help prevent?

In industrial environments where flammable materials are handled, flame detection systems are crucial for safety.

|

The FL5000 flame detector provides superior false alarm discrimination over long distances |

They serve as an essential layer in safety programmes, helping to prevent fires and explosions by detecting the presence of flames early on.

However, false alarms can be a significant issue, disrupting operations and potentially desensitising personnel to real alerts.

Different flame detection methods exhibit varying false alarm profiles depending on the application, which is why advanced diagnostic technologies, like artificial neural networks (ANNs), have been developed to enhance these systems and reduce false alarms.

What are the challenges faced by traditional flame detection systems?

Traditional flame detection systems rely on sensors such as infrared (IR) and ultraviolet (UV) detectors to identify flames. These sensors, however, can be prone to interference from sources like sunlight, arc welding, and hot surfaces, which may lead to false alarms.

Environmental factors like dust, smoke, and fog can further limit the effectiveness of flame detectors, making it challenging to distinguish between genuine threats and false alarms.

How do advanced diagnostic technologies, particularly ANNs, address these challenges?

ANNs are a powerful solution to these challenges. They are computational models inspired by the structure and function of the human brain, capable of learning complex patterns and making decisions based on vast datasets.

When applied to flame detection, ANNs can discern subtle differences between actual flames and potential sources of interference, significantly reducing false alarms.

Can you explain how ANNs work in the context of flame detection?

ANNs are trained using extensive datasets of spectral data from both real flames and common sources of interference.

Through supervised learning, the network adjusts its internal parameters to optimise its ability to accurately classify input data.

Once trained, the ANN can quickly analyse incoming sensor data and determine whether a detected anomaly corresponds to a genuine flame or a false alarm. Since 2005, MSA has been at the forefront of using artificial neural networks in flame detection technology.

What industries have embraced ANNs for flame detection, and what results have they seen?

Numerous industries, including oil and gas, chemical processing, and manufacturing, have adopted ANNs for flame detection with remarkable results. By integrating ANNs into their safety systems, companies have reported significant reductions in false alarms, leading to enhanced operational continuity and improved worker safety.

Additionally, the scalability of ANNs allows them to be deployed in diverse environments, from offshore platforms to industrial plants, highlighting their versatility and effectiveness.

What are the key advantages of using ANNs in flame detection?

The key advantages of using ANNs in flame detection include:

• Adaptability: ANNs can handle varying environmental conditions and sources of interference due to their extensive training library, making them robust in real-world applications.

• Accuracy: ANNs leverage sophisticated pattern recognition capabilities to differentiate between genuine flames and false alarms with high precision.

• Efficiency: ANNs can process large volumes of data in real-time, enabling rapid decision-making and minimising response times in critical situations.

• Reduced Maintenance: With fewer false alarms, flame detection systems that incorporate ANNs require less frequent maintenance, resulting in cost savings and improved operational efficiency.

Can you introduce us to the latest generation of flame detectors, the General Monitors® FL5000 MSIR Flame Detector?

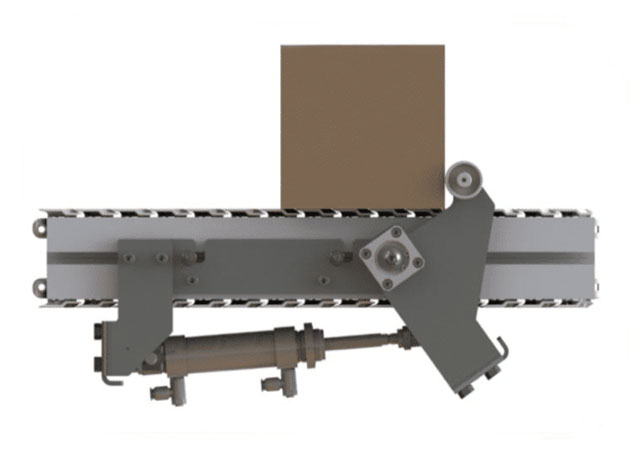

The FL5000 Multi-Spectrum Infrared (MSIR) Flame Detector is MSA Safety’s latest generation flame detector.

It builds on the foundation set by the FL4000H, with increased neural network capabilities that further reduce false alarms. The proprietary MSIR flame algorithm ensures that the detector verifies the presence of a legitimate flame before initiating an alarm, protecting both assets and budget.

Additionally, the FL5000 is the first flame detector to incorporate Bluetooth technology. With the exclusive Flame Connect App, users can easily set up, configure, and download event logs from mobile devices.

How do advanced diagnostic technologies, like ANNs, benefit industrial flame detection?

Advanced diagnostic technologies, especially artificial neural networks, offer excellent accuracy and efficiency in flame detection while minimising false alarms.

By harnessing the power of ANNs, industries can mitigate risks, protect assets, and safeguard personnel.

As technology continues to evolve, the integration of next-generation ANNs is poised to set new benchmarks for excellence in industrial flame detection.

Finally, regarding the previous model, the FL4000H. Would you recommend users with the FL4000H fleet to think about upgrading their flame detection system with the FL5000 detector?

Yes, there are quite a few good reasons to consider upgrading. First, the FL5000 was designed with the same footprint as the FL4000H/FlameGard 5 MSIR Flame Detector, making it easy to upgrade without needing to run new conduit or pour new seals. Plus, it uses the existing bracket (P/N 71370-1).

Simply remove the FL4000H optical housing and wiring from the FL4000H relay board, and you can use the FL5000 Upgrade Kit to retrofit your FL4000H flame detector with the new features of the FL5000 and get a new five-year warranty.

Just make sure to check your electrical specifications to ensure the FL5000 meets all the requirements of your current installation, such as maximum power output and wiring distance.

* Kevin Killeen is the Global Product Line Manager for Flame Detection at MSA Safety. He is tasked with the development and maintenance of MSA’s Flame Detection products such as the FL500 UVIR and FL5000 MSIR Detectors. He has been with MSA for almost two years and has a further four years of experience in the industrial automation industry, specialising in electrical instrumentation.