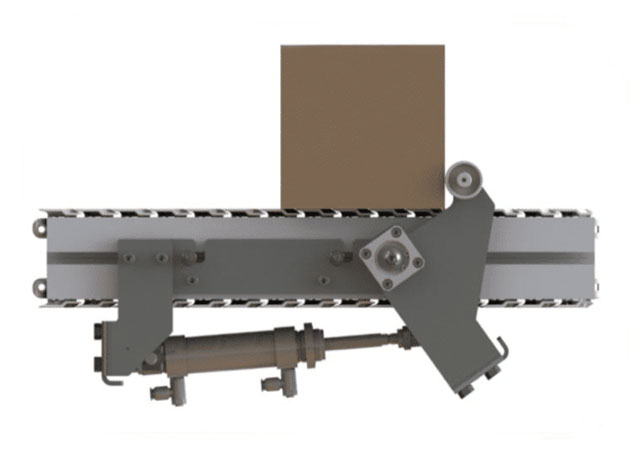

Start-up of the large-scale electrically heated steam cracking furnace

Start-up of the large-scale electrically heated steam cracking furnace

As it continues to push the boundaries of science and technology, SABIC is demonstrating that sustainable business practices are not only viable but essential for long-term success

In a world increasingly focused on sustainability, SABIC, a global leader in diversified chemicals, is setting a high standard for corporate responsibility.

With a commitment to pioneering eco-friendly solutions, the company has implemented a wide array of initiatives aimed at enhancing its sustainability performance.

From advanced recycling technologies to low-carbon ammonia production, SABIC is determined to lead the charge towards a greener future.

The company not only aims to reduce its environmental footprint but also seeks to empower its customers and communities by providing sustainable alternatives across a variety of sectors.

Since 2020, SABIC has embraced a comprehensive methodology developed by the World Business Council for Sustainable Development (WBCSD) to conduct sustainability assessments across its product portfolio.

This approach reflects a deep understanding that sustainability is not merely an add-on to business practices but rather an essential component of the company's overall strategy.

In 2023, this effort expanded significantly, with 63 per cent of the company's total revenue now assessed up from 48 per cent in 2022.

This rigorous evaluation process not only drives internal improvements but also ensures that customers receive sustainably sourced products that meet the growing demand for environmental responsibility.

The company’s commitment to innovation is further illustrated by its impressive output of patent applications.

In 2023 alone, SABIC filed 224 patent applications, 40 per cent of which focused on enhancing environmental attributes.

This commitment to research and development serves as a testament to SABIC's strategy of integrating sustainability into its core business practices.

By actively pursuing innovative solutions, SABIC is not only addressing current environmental challenges but is also preparing to meet the future needs of its customers and stakeholders.

RECOGNITION AND AWARDS

|

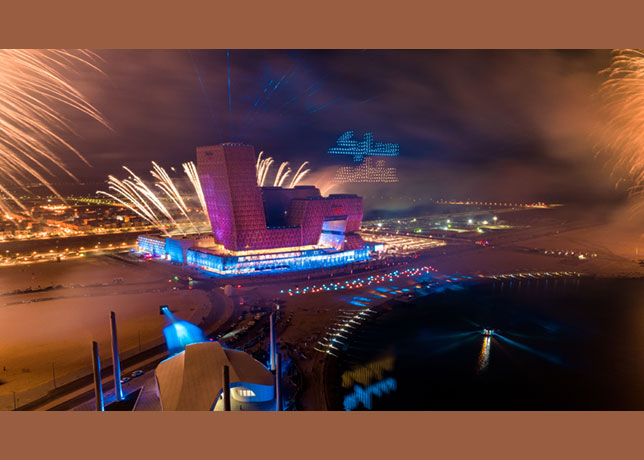

SABIC's advanced recycling unit in Geleen, The Netherlands |

SABIC's efforts in sustainability have garnered significant recognition within the industry. In 2023, the company received five Edison Awards for product innovation, reflecting its commitment to excellence and creativity in developing sustainable solutions.

Among these accolades, the R&D 100 Award for its LNP™ ELCRES™ CRX copolymer resin highlights the company’s dedication to creating high-performance materials with a reduced environmental impact.

Furthermore, Bob Maughon, SABIC's Executive Vice President of Technology and Innovation, was honoured as ‘R&D Sustainability Innovator of the Year’.

This recognition not only underscores Maughon’s leadership in driving sustainability initiatives but also reflects SABIC's culture of innovation and excellence.

Ambitious Sustainability Goals

Among the highlights of SABIC's sustainability agenda are its ambitious targets for carbon neutrality and circularity.

In early 2023, SABIC set a goal to process at least 1 million metric tonnes of TRUCIRCLE™ products annually by 2030, sourced from bio-based or recycled feedstock.

This ambitious goal aligns with the company’s vision of fostering a circular economy where materials are reused and recycled, thus minimising waste.

The launch of the Circular Technology Road Map in October 2023 lays out a strategic framework to achieve this target, commencing with a significant processing of 18,000 metric tonnes this year.

This initial step demonstrates SABIC's commitment to building a strong foundation for future partnerships and collaborations that will enhance its capacity in sustainable materials.

SABIC’s investment in advanced recycling technologies further exemplifies its commitment to a circular economy.

The company is on track to open a commercial plant for advanced recycling in Geleen, The Netherlands, in 2024.

This facility will significantly boost SABIC’s ability to process and recycle plastics, transforming waste into valuable resources that can be reintroduced into the production cycle.

By facilitating the recycling of plastic waste, SABIC not only contributes to reducing landfill waste but also supports the development of sustainable materials that meet customer demands.

DRIVING INNOVATION THROUGH COLLABORATION

Collaboration is key to SABIC's sustainability strategy. The company has partnered with industry leaders BASF and Linde to develop the world’s first large-scale electrically heated steam-cracker furnace, which aims to reduce CO2 emissions by, at least, 90 per cent compared to conventional technologies.

The last transformer for this groundbreaking facility was installed in September 2023, with commissioning set to begin in early 2024. This partnership exemplifies the potential of collaborative efforts in driving innovation and achieving significant environmental benefits.

SABIC has also made strides in the bioeconomy with the introduction of bio-based NORYL™ resin grades, certified under the ISCC PLUS scheme.

This initiative showcases SABIC's dedication to renewable plastic solutions that can be applied across various industries, from automotive to construction.

By offering bio-based alternatives, SABIC is not only enhancing its product portfolio but also helping its customers transition towards more sustainable practices.

In the agricultural sector, SABIC Agri-Nutrients has emerged as a pioneer by introducing certified low-carbon ammonia to the Indian fertilizer market.

This significant milestone marks a crucial step in decarbonising agricultural practices and reflects SABIC's commitment to providing low-carbon solutions that contribute to a more sustainable food supply chain.

The shipments of low-carbon ammonia and urea to various international markets, including Japan and New Zealand, underscore SABIC's ambition to be a leading player in the low-carbon ammonia market, further promoting sustainable agricultural practices.

TACKLING PLASTIC WASTE

The chemical recycling of plastic waste is another cornerstone of SABIC's sustainability initiatives.

In a groundbreaking project, SABIC collaborated with Saudi Aramco and TotalEnergies to successfully convert oil derived from plastic waste into ISCC PLUS certified circular polymers.

This project addresses the challenge of end-of-life plastics, utilising non-sorted plastics that are often difficult to recycle mechanically.

The ability to convert these materials into valuable feedstock represents a significant advancement in tackling plastic waste, demonstrating SABIC’s leadership in the circular economy.

The first milestone of this project was obtaining ISCC PLUS certification, which assures transparency and traceability of the recycled origin of feedstock and products.

This level of certification is crucial in building consumer trust and ensuring that the products meet stringent sustainability standards.

The pyrolysis oil produced from this initiative was processed at the SATORP refinery, a joint venture between Saudi Aramco and TotalEnergies, and subsequently used as feedstock for polymers manufactured by SABIC’s affiliate Petrokemya.

CARBON CAPTURE TECHNOLOGIES

SABIC’s proprietary carbon capture technology is another significant aspect of its sustainability agenda.

The carbon capture and utilisation (CCU) plant at the Jubail United Petrochemical Company captures and purifies up to 500,000 metric tons of CO2 annually, repurposing it as valuable feedstock for various applications.

This facility, opened in 2015, remains one of the largest CCU plants globally, highlighting SABIC's commitment to leveraging cutting-edge technology to address climate change.

The high purity of processed CO2 produced at the CCU plant is considered food grade, allowing it to be used in a range of commercial and industrial applications, from fertilisers to medical products.

This integrated approach not only reduces emissions but also creates new market opportunities, reinforcing SABIC's commitment to sustainability as a core principle of its operations.

By effectively capturing and utilising CO2, SABIC demonstrates that environmental responsibility can go hand in hand with business growth.

Moreover, SABIC was established by royal decree to convert waste natural gas into valuable chemicals, aligning with its founding principles of innovation and sustainability.

This long-standing commitment to creating value from waste reflects the company’s ongoing dedication to pushing the boundaries of science and technology in pursuit of a more sustainable future.

LOOKING AHEAD

As the world navigates the transition to a low-carbon economy, SABIC remains steadfast in its mission to innovate and lead in sustainable practices.

The company’s approach is guided by its vision of a circular carbon economy, which aims to create a system where all value chains loop back on themselves.

This vision encompasses not only product design and development but also the optimisation of industrial processes, including the capture and utilisation of carbon-containing gases as valuable feedstock.

By focusing on the four pillars of sustainability reduce, reuse, recycle, and remove SABIC is advancing a comprehensive strategy that addresses the multifaceted challenges of climate change and resource scarcity.

The company's commitment to reducing its carbon footprint while providing innovative, sustainable products positions it as a leader in the global transition towards a more sustainable future.

SABIC’s leadership in sustainability also extends to engaging with stakeholders, including customers, suppliers, and communities, to drive collective action.

By fostering partnerships and collaborations, SABIC aims to amplify its impact and encourage a broader commitment to sustainability within the industry.

In conclusion, SABIC is not just adapting to the challenges of sustainability; it is actively shaping the future.

Through its ambitious goals, innovative technologies, and collaborative efforts, the company is setting a benchmark for corporate responsibility in the chemical industry.

As it continues to push the boundaries of science and technology, SABIC is demonstrating that sustainable business practices are not only viable but essential for long-term success.

With a clear vision and unwavering commitment, SABIC is poised to lead the way in creating a more sustainable world for generations to come.

By Abdulaziz Khattak