Hani Alkhalifah

Hani Alkhalifah

The Lummus SRT-h Hybrid Heater offers a scalable path to near-zero CO2, Hani Alkhalifah, Manager of Technical Life Cycle Services – MENA, tells OGN

As the global refining and petrochemical industries face increasing pressure to decarbonise, electrification of fired heaters has emerged as a promising solution to reduce CO2 emissions.

However, transitioning from conventional hydrocarbon-fired heaters to fully electric systems present significant challenges, including high capital investment, infrastructure limitations, and return on investment.

At Lummus, we recognise that the journey to net-zero is not a one-size-fits-all transformation, but rather, a phased and practical evolution.

|

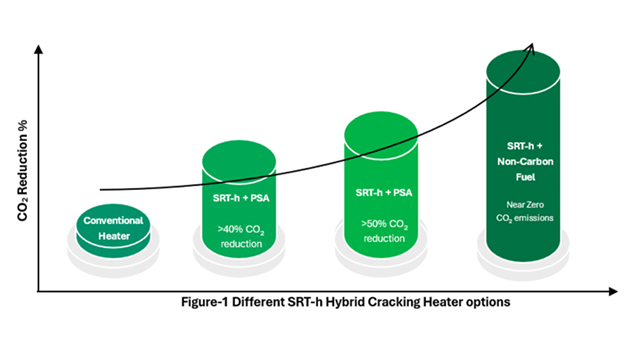

Figure 1 ... a comparison of emissions reductions a refinery or petrochemical plant can achieve with different |

We offer the SRT-e™ Electric Cracking Heater, a fully electric heater solution designed for greenfield projects and customers ready for complete electrification.

But we also understand that many refining and petrochemical operations are working within the constraints of the capex, infrastructure, and investment challenges listed above.

That’s why Lummus developed the SRT-h™ Hybrid Cracking Heater as a balanced approach that enables unit owners to significantly reduce CO2 without the need to demolish and replace an entire fired heater.

Operators can retrofit their existing units to create an SRT-h Hybrid Cracking Heater that integrates electric heating with traditional fuel firing.

This technology supports immediate emissions reduction and operational continuity, while keeping the door open for future upgrades that target near-zero CO2 emissions.

Transitioning a conventional fired heater into a hybrid system isn’t a short-term fix, it’s a strategic move.

The SRT-h Hybrid Cracking Heater can be implemented in phases, starting with partial CO2 emission reduction and later progressing toward near-zero emissions when combined with non-carbon fuel firing solutions (Figure 1).

HYBRID CRACKING HEATER CONCEPT

|

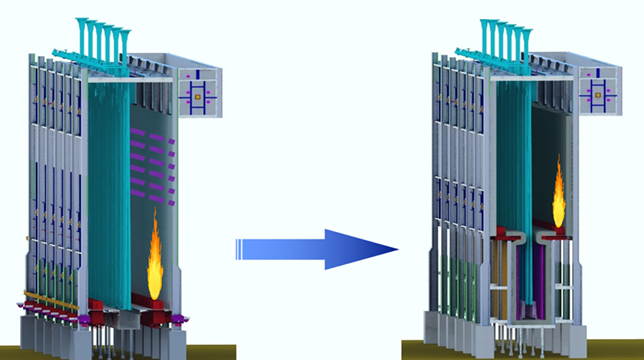

Figure 2 ... conventional cracking heater (left) and hybrid cracking heater (right) |

The SRT-h Hybrid Cracking Heater technology integrates both fuel firing and electric heating to reduce the reliance on hydrocarbon fuels in gas and liquid cracking heaters (Figure 2).

This approach reduces CO2 emissions by up to 40 per cent without affecting plant throughput or disrupting the steam balance.

Importantly, it achieves these environmental benefits while maintaining stable performance in the recovery section.

The electrical heater and fuel firing system co-exist in the radiant section of the hybrid cracking heater.

This hybrid design utilises the same coil and layout as a conventional heater but incorporates electrical heating in the lower radiant section to achieve a more even heat distribution and mitigates the risk of overheating.

Electrical heating will cover 15-25 per cent of the total heat requirements, while fuel firing will cover 75-85 per cent of the total heat requirements.

PERFORMANCE OF HYBRID CRACKING HEATER

|

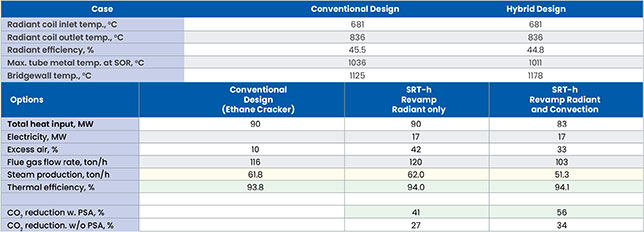

Table 1 ... performance of hybrid cracking heater |

To evaluate the performance of the hybrid cracking heater concept, a commercial ethane cracker (SRT III) was converted to a hybrid heater.

After conversion, total fuel fired reduced from 89.7 MW to 73.6 MW, with an electrical input of 16.1 MW. Hearth burners were moved higher, and wall burners were no longer needed.

To maintain steam production, the hybrid heater operates at 42 per cent excess air, keeping heat input to the convection section unchanged.

The hybrid design changes the radiant box geometry compared to a conventional heater, which affects airflow and reduces the space available for combustion.

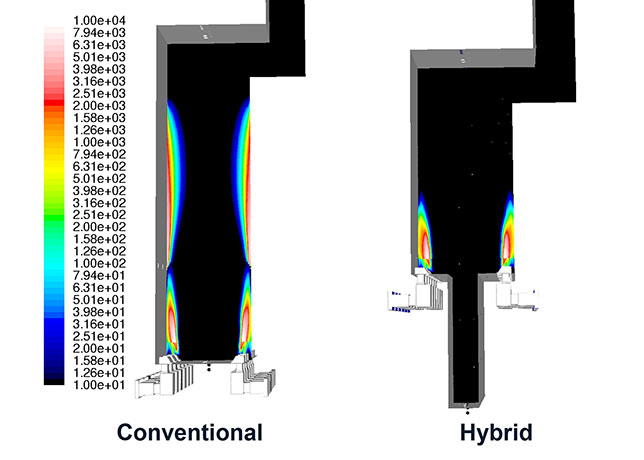

Computational fluid dynamics (CFD) modeling confirmed that combustion is complete before gases enter the convection section, avoiding flame rollover or poor distribution.

Figure 3 shows smooth flame patterns and CO levels below 1000 ppm.

CFD results match plant data closely and help optimise design and troubleshoot issues (Table 1).

KEY ADVANTAGES OF SRT-H HYBRID CRACKING HEATER

|

Figure 3 ... CO profile in conventional and hybrid cracking heaters |

The SRT-h hybrid heater is engineered for retrofitting existing fired heaters with minimal modifications, offering a practical and cost-effective solution for reducing carbon emissions.

It enables up to a 40 per cent CO2 reduction, maintains existing infrastructure, and can be implemented without requiring a full unit shutdown.

The revamp avoids major impacts on plant capacity and steam balance, making it ideal for operational continuity and budget-sensitive operations.

As the refining and petrochemical industries continue working to reduce carbon emissions, fully electric heaters offer a long-term solution.

However, they come with high costs, infrastructure challenges, and operational risks.

Lummus Technology’s SRT-h Hybrid Cracking Heater provides a more balanced and practical alternative for the near term.

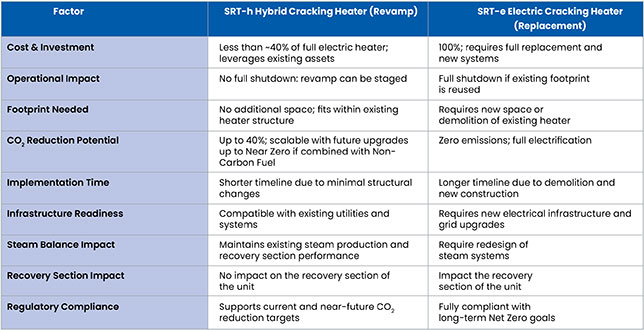

When considering decarbonisation options for existing fired heaters, Table 2 compares the key factors between retrofitting with the SRT-h Hybrid Cracking Heater and replacing with the SRT-e Fully Electric Cracking Heater (Table 2).

|

Table 2 ... a comparison of capex, infrastructure, and CO2 reduction potential between the SRT-h and SRT-e cracking heaters |

In conclusion, compared to fully electric systems, which require new infrastructure and complete replacement, the SRT-h Hybrid Cracking Heater offers a cost-effective solution that aligns with current operational realities.

It also lays the groundwork for future near-zero CO2 emissions, making it an ideal step toward long-term sustainability goals.