Made in KSA ... Canrig’s automated power catwalks are revolutionising drilling operations by enhancing safety, efficiency, and performance

Made in KSA ... Canrig’s automated power catwalks are revolutionising drilling operations by enhancing safety, efficiency, and performance

Nabors Industries continues to lead in transforming drilling operations through automation and digitalisation with its SmartROS® rig automation system and RigCLOUD® digital platform

Nabors’ SmartROS® rig automation system and RigCLOUD® digital platform are revolutionising the industry by providing real-time data insights and making automation accessible and deployable on any AC rig extending their benefits beyond Nabors’ own rig fleet.

These technologies are designed to enhance operational efficiency, minimise downtime, and ensure precise drilling performance, consistently reducing or eliminating drilling operations zero non-productive time (NPT).

Nabors’ RigCLOUD® optimisation platform has been instrumental in digitalising operations across the Eastern Hemisphere, providing real-time data and drilling analytics enabling operators to make more informed decisions.

Uniquely designed to host drilling and analytics software at the rig site, on the web, and on mobile devices, the RigCLOUD® automation platform ensures seamless acquisition, storage, management, visualisation, and delivery of drilling data, including efficient transmission from the Wellsite Information Transfer Standard Markup Language (WITSML) stores for enhanced interoperability and data accessibility.

Its reliable system enables efficient communication across applications to support digital operations while ensuring secure access to data and services for integration with other digital systems and partner applications.

|

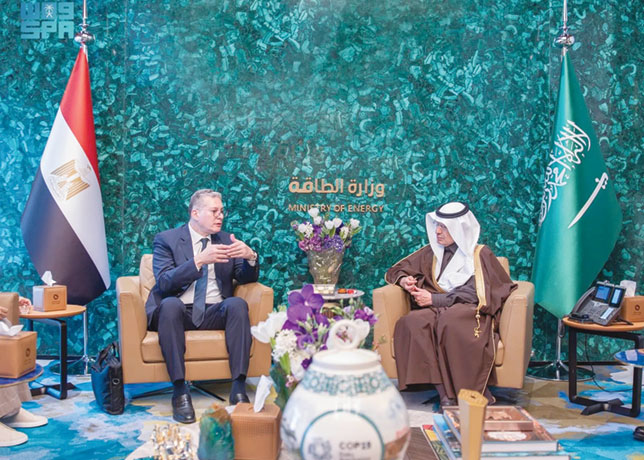

Nabors' KSA team |

Deployed on over 40 rigs in Saudi Arabia and 27 rigs across the Middle East, Africa, Far East, Russia, and Kazakhstan, including non-Nabors rigs, the RigCLOUD® platform has proven its adaptability and impact by enhancing efficiency and enabling data-driven decision-making across diverse operations.

Further strengthening its reliability, the platform is supported by RigLINE® 24/7, providing continuous assistance and expert guidance to optimise performance and ensure seamless operations.

Meanwhile, the SmartROS® rig operating system stands out for its versatility and scalability.

Designed for drillers by drillers, this modular, capital-light system enables customisable purpose-fit drilling automation solutions while ensuring consistent, repeatable performance.

This is accomplished by replicating best-in-class workflows, driving consistency, and maximising performance across the rig fleet.

Currently, Nabors’ SmartROS® operating system is installed on over ten rigs in the region, delivering successful results and elevating operations for customers in Iraq, Oman, Saudi Arabia, and Papua New Guinea.

Globally, the SmartROS® system has supported over 120 customers in drilling more than 5,000 wells across 150 rigs, utilising its SmartDRILL®, SmartSLIDE®, and SmartNAV® advanced drilling automation solutions.

|

Nabors’ new Automation Intelligence portfolio is redefining drilling optimisation |

In Oman and Iraq, Nabors’ SmartROS® system was implemented on 8 out of 14 wells, achieving a 43 per cent reduction in weight-to-weight time in the vertical section and 34 per cent in the lateral section when compared to the offset, ensuring consistency across diverse rigs and control systems.

In Saudi Arabia, the SmartROS® automation platform was deployed across three rigs to drill 14 wells, achieving substantial time savings in weight-to-slip and slip-to-weight transitions, the key components of automation efficiency.

The results surpassed the operator’s benchmark, with time reductions of 29 per cent for the 22-inch hole section, 27 per cent for the 16-inch hole section, and 33 per cent for the 12-inch hole section, demonstrating the platform’s ability to enhance drilling performance and efficiency.

These results underscore the efficiency, reliability, and scalability of Nabors’ automation solutions, driving safer and more cost-effective drilling operations.

TRANSFORMING DRILLING WITH AUTOMATION INTELLIGENCE PLATFORM

Nabors’ new Automation Intelligence portfolio is redefining drilling optimisation by enhancing efficiency, reducing costs, and improving decision-making.

Early deployments for a major operator in Saudi Arabia have already demonstrated impressive results, with savings of over 20 hours on two wells.

By analysing BHA health, optimising ROP, and integrating seamlessly with auto-drillers, Nabors Automation Intelligence platform empowers operators to make real-time, data-driven decisions, expediting operations, improves performance, and generates significant cost savings across multiple wells, reinforcing Nabors’ commitment to advancing drilling automation.

ILLUMINATING NIGHTTIME OPERATIONS WHILE LOWERING CARBON EMISSIONS

Canrig’s ILLUMIC™ Lighting System has delivered significant operational benefits across the Middle East and Asia.

Recent performance results from 19 rigs in Saudi Arabia alone have led to savings of over 78,000 gallons of fuel, more than 900,000 kWh of energy, and a reduction of over 800 metric tons of carbon emissions.

These savings not only contribute to cost efficiency but also improved nighttime operations, enhanced safety and operational efficiency contributing to more sustainable drilling practices.

STRENGTHENING LOCAL MANUFACTURING AND REPAIR CAPABILITIES

Canrig’s Made in KSA automated power catwalks are revolutionising drilling operations by enhancing safety, efficiency, and performance.

Built entirely in the Kingdom, these advanced catwalks streamline casing delivery to the drill floor, eliminating manual handling and reducing the need for additional services at the wellsite.

Canrig’s KSA manufacturing facility continues to drive innovation and local content development, having already delivered over eight PC4000 Catwalks and more than six PC8000 Catwalks, with additional units scheduled for delivery this year.

As an original equipment manufacturer (OEM), Canrig repairs, recertifies and upgrades a broad range of equipment types, including those produced by third party.

By driving automation, digitalisation, and sustainability, Nabors continues to lead the transformation of drilling operations in the Middle East and beyond.