The M2M Mantis ... a superior NDT solution

The M2M Mantis ... a superior NDT solution

Eddyfi Technologies’ M2M Mantis uses modern NDT methods to detect even the slightest corrosion, welding defects, and other damage mechanisms prevalent in the energy sector

Non-destructive testing (NDT) is at the centre of ensuring the safe operation of assets like pipelines, pressure vessels, and storage tanks commonly found in the oil and gas sector, which relies on high performance with maximum efficiency especially in a volatile economy.

The same expectations should be made of the tools responsible for providing data to help determine the remaining useful life of these critical components, a spokesman for Eddyfi Technologies tells OGN.

Eddyfi Technologies designs and manufactures the most advanced NDT inspection technologies in the world that assist asset owners and service providers with their strong risk management operations.

Having recently undergone a complete transformation, the M2M Mantis is an industry-leading flaw detector designed to fully exploit ease of transportation with ultimate capabilities in the field.

|

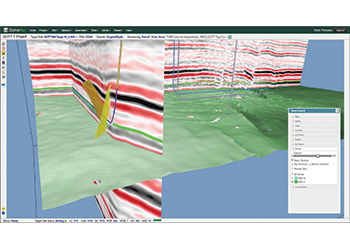

3-axis encoding creates a compelling visualisation |

According to the spokesman: "Corrosion, welding defects, and other damage mechanisms prevalent in the energy sector do not stand a chance of being left undetected by this cost-effective instrument that offers conventional ultrasonic testing (UT), phased array ultrasonic testing (PAUT), time-of-flight-diffraction (TOFD), and total focusing method (TFM)."

Based on a 16:64PR architecture with three different models, Mantis is directly applicable to a complete spectrum of industrial inspection applications without compromising on productivity.

Careful consideration has been given to the highly durable materials chosen for this robust unit, which has successfully passed demanding environmental and endurance tests designed to mimic real-world situations.

From a hardware point of view, the new M2M Mantis can be held in one hand making it ideal for inspections requiring rope access, typical of offshore platforms. The unit incorporates one internal battery that is hot-swappable for longer inspections.

Faster data transfer and remote-controlled inspections in challenging environments are enabled through Wi-Fi, a USB 3.0 connector, and Gigabit Ethernet output with TeamViewer license included. The instrument’s bright resistive touch screen is glove compatible with a magnetic stylus also available for operators.

.jpg) |

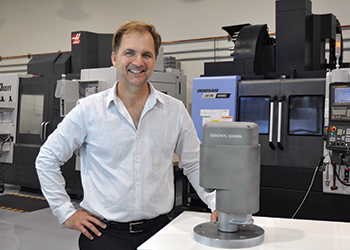

Nozzle inspection using M2M Gekko |

The most popular connectors including IPEX PA, LEMO-00 UT and LEMO-16 encoder connectors are all incorporated in the M2M Mantis allowing inspectors to readily use their own probes, scanners, and accessories.

This multi-technology tool is powered through a streamlined acquisition and analysis software interface called Capture. It truly is a complete package designed for all levels of technicians.

Featuring simple three-click calibration wizards, Capture empowers inspectors to improve their knowledge without extensive training.

Eddyfi Technologies offers two major software updates a year to keep operators Beyond Current.

In the latest software release, a new TFM method called plane wave imaging (PWI) improves scan speed and sensitivity. There are tools onboard to ensure code compliance including amplitude fidelity and time corrected gain (TCG).

Recognising that the analysis stage can sometimes be the most time-consuming process when it comes to planning maintenance and/or replacement activities based on the integrity of an asset, Capture includes advanced analysis tools to increase productivity. When defects are found, an auto-sizing feature automatically provides its dimensions so operators can determine whether it is critical.

Being able to export data in 3D allows the visualisation of ultrasonic data superimposed on the model of the component under examination to remove any guesswork. For example, there is a nozzle inspection application that allows operators to define key characteristics that enable reliable nozzle-to-shell weld evaluation.

An important variable for inspecting in spaces like nozzle geometry, 3-axis encoding creates a compelling visualisation. The M2M Mantis produces an on-screen component with calculated cross-sections of the nozzle overlay in real-time, superimposed into a sectorial scan.

When inspections require more than one file to cover the entire asset, C-scan stitching is available for corrosion mapping, High Temperature Hydrogen Attack (HTHA), Hydrogen Induced Cracking (HIC), and other more intensive inspections required by the oil and gas sector. As there is no file size limitation with Capture, large areas can be inspected without an issue.

Even the entry level M2M Mantis benefits from these state-of-the-art analysis tools that help operators perform efficient and reliable examinations.

The 16:64PR model is the most affordable solution for corrosion mapping. It can be configured for automated scans when paired with our RMS scanner. Alternatively, Capture software offers helpful tools to calibrate the resolution for handheld scanners, transforming a 3-axis freehand motion into a Cartesian grid.

With a single group, dual linear array or DLA probes can be used and take into account curved wedges for seam welds of oil and gas pipelines.

The Mantis 16:64PR TFM16 model offers multi-group configurations which make it ideal for weld inspections using two PAUT and a pair of TOFD probes. Basic TFM applications can also be employed.

Finally, the 16:64PR TFM unit unlocks the full potential with TFM up to 64 elements with high pulse repetition frequency (PRF) for inspection of complex components like fillet welds and nozzles found on pressure vessels and tanks.

"The M2M Mantis is a superior NDT solution that allows operators to evaluate the conditions of some of the most challenging environments found in oil, gas and petrochemical facilities, offering the key to successful prevention through routine checks in turnaround season, maintenance processes and safety plans," concludes the spokesman.

More information on how the M2M Mantis can increase time and production efficiencies in operations can be found at www.eddyfitechnologies.com or by email at info@eddyfi.com.

.jpg)