Genuine loop-powered flowmeter

Genuine loop-powered flowmeter

Maintaining asset integrity in the oil and gas industry, onshore or offshore, is a costly affair. Expensive chemicals are used in the production platforms and are dosed or injected in transmission pipelines to protect it from corrosion, preventing wax formation, scaling, foaming and to inhibit any kind of deposits. These expensive chemicals include wax and corrosion inhibitors, demulsifiers, dilutants, biocides, methanol, and water treatment chemicals.

To keep opex in control, it is imperative that these chemicals are dosed in just the right quantity to protect the assets, says Apurva Sharma, Industry Manager - Oil and Gas, Endress+Hauser Middle East.

'Any overdosing is just a waste of the chemicals without bringing in any benefits in terms of pipeline integrity. Injected chemicals must be just enough for asset protection, but no more than this as it would only result in unnecessary use of expensive chemicals,' he adds.

In order to control the amount of injection to an optimum value, it is important to measure the injected chemical quantity accurately. As the saying goes in the process control world - 'you cannot control the process optimally unless you measure it accurately', comments Sharma.

|

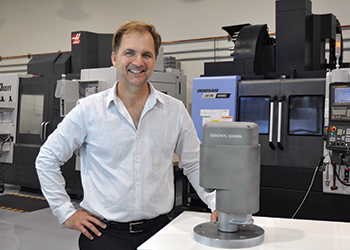

The flowmeter in an installation |

To achieve the objective of measuring the chemical accurately and hence controlling the injection optimally, the preferred technology of today’s forward-thinking process owners is the Coriolis technology. 'When every drop matters, accurate measurement of chemicals with Coriolis flowmeter technology provides best-fit solution. Today, the modern technology of Coriolis flowmeters enables the process owners to both optimise their productivity and minimise their opex, thanks to reliable performance,' says Sharma.

In addition, the absence of non-moving parts in Coriolis flowmeters provides significant savings in reduced maintenance and corresponding efficiency gains compared to conventional flow measurement technologies. The savings achieved by avoiding over-injection of chemicals can be quite significant, explains Sharma. 'The ROI of a Coriolis flowmeter on a chemical injection system can be reached in just a few months thanks to the highly accurate measurement of the expensive chemicals used by avoiding costly over injection.

With an innovatively designed Proline Promass A, Endress+Hauser provides a fit-for-purpose Coriolis meter. Sharma says Proline Promass A was developed with chemical injection in focus, adding that the smallest flow rates of just a few grams per minute (g/min) can be measured with unprecedented repeatability, stability and accuracy.

MAXIMUM PRECISION

Elucidating the features, Sharma says, the Promass A sensor system is mounted on a base plate that acts as a ‘shock absorber’, effectively shielding the Coriolis measurement from outside interference, for example, from pipe vibrations.

Other contributing factors are the oscillation frequency of the measuring tube, which is significantly higher than that of traditional Coriolis flowmeters, and its completely balanced oscillation behaviour.

At a specified maximum measured error of ±0.1 per cent, high precision measurements down to 8 g/min are possible. And, if the maximum error of ±1 per cent is permitted, then even a quantity of less than 1 g/min can be measured, a top value for Coriolis flow measurement technology.

Promass A is a Coriolis flowmeter that meets most of the specifications defined by process owners. The enhanced low-flow performance has improved the accuracy levels for the most challenging applications. A two-wire instrumentation on the skids is usually preferred since it reduces cost, complexity and weight as no external power supply is needed.

'With the introduction of the Promass A 200, the demand for a loop-powered Coriolis flowmeter is met. In addition, it’s intrinsically safe Ex concept and the corresponding safety gains are added benefits,' concludes Sharma.

.jpg)