Yasin ... looking at well system dynamics proactively

Yasin ... looking at well system dynamics proactively

To address the challenges in fracture flow diagnostics, TGT has developed a system that comprises the Fracture Flow and Multi Seal Integrity products

According to a recent report by the International Energy Agency (IEA) one of the three areas that stood out as an implication of the pandemic, was ‘Energy security’.

Although the global demand for oil is unlikely to return to 2019 levels, until 2022-2023, there is still a call to satisfy and secure more energy through hydrocarbon production. As ‘easy oil’ draws down, energy companies are turning to other means of extraction.

Advances in horizontal drilling and hydraulic fracturing technology has made less traditional oil and gas sources more accessible. Overtime, the cost of extraction has decreased. However, the efficiency of extraction still needs improvement, Maged Yassin, Business Unit Manager, KSA and Bahrain, tells OGN.

He says: "Major improvements to hydraulic fracturing programmes are possible if operators had access to comprehensive pre- and post- fracture evaluations. This information would provide data that would aid better informed decisions to optimise the fracture programme."

Traditional techniques for fracture evaluation come in the form of Production Logging Tools (PLT), but with its vision limited to wellbore flow, this technique struggles to evaluate such complex flow regimes.

OPTIMISING FRACTURE FLOW

|

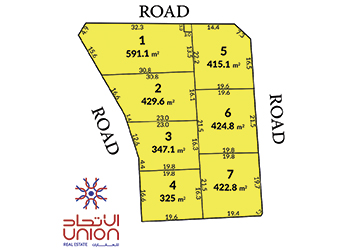

A survey summary |

TGT has developed a diagnostic system for fracture flow diagnostics. It provides two products to address these challenges: ’Fracture Flow’ and ‘Multi Seal Integrity’.

Fracture Flow can locate and evaluate fracture inflows and quantify inflow profiles, while Multi Seal Integrity confirms the integrity of the well system by validating the sealing performance of multiple barriers.

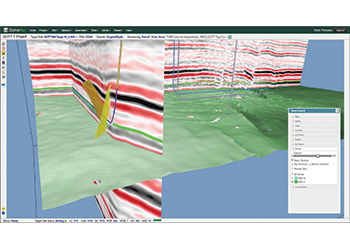

These products are delivered via combining several technology platforms: Chorus (acoustic), Cascade (thermal), Indigo (multisense) and Maxim (digital workspace). Data is acquired via a tailored diagnostic program prepared to match diagnostic objectives and well conditions.

Fractures can be generated by hydraulic fracturing, where abnormally high differential pressures are applied to the reservoir. The fluid dynamics of flow through fractures generation is considerably different to that of reservoir flow and can be likened more to the process that takes place when the flow propagates through tube or cement channels.

Unlike flow through a channel in the cement, fracture flow is more confined to a specific reservoir interval. The acoustic power spectrum of sound energy generated by a fracture flow is associated not only with flow velocity, but also fracture ‘openness’.

In other words, the characteristic signature of acoustic energy generated by fluid flowing through fractures is unique and can be distinguished from the acoustic signatures generated by other sources, such as fluid flowing through the wellbore or the reservoir.

CASE STUDY: SPE PAPER 191735-MS

According to the SPE-191735-MS technical paper, entitled ‘Complete Assessment of Complex Unconventional Saudi Arabian Producer Using High Definition Spectral Noise Logging and Numerical Temperature Modelling’, a fracture flow assessment was required for a horizontal tight sand gas condensate producer, with 3,500 ft of lateral length.

The well was completed with a non-cemented multistage ball-activated sleeve system. Stage separation was achieved by dual hydraulically activated packers. The completion had seven stages with the intention of placing 19 fracture clusters.

Alongside the conventional wellbore flow distribution, additional diagnostic results were required to:

• Evaluate the integrity of several swellable ‘slip-on’ packers separating the entry port sleeves at each stage;

• Evaluate the integrity of the hydraulically activated packers separating the stages;

• Assess the number of flowing fractures which resulted from the fracturing operation;

• Determine the effectiveness of the limited entry frac ports.

The operation was carried out under flowing and shut in conditions.

The interpretation of the acquired data for the ‘Fracture Flow’ product identified the presence of 22 active fracture clusters. The fracture distribution varied between stages, as shown in Figure 1. The results confirmed the success of the fracturing operation and the suitability of the formation for this type of fracture programme.

‘Multi Seal Integrity’ results showed that the completion’s integrity was good. The diagnostics confirmed that the three bypassed hydraulic packers and two bypassed swellable constrictors were working well, with no major influence on the total stage contribution, shown in Figure 1. Note, the production seen in stages 4 and 7 were as a result of unplanned fractures created between the dual hydraulic packers.

THE RIGHT SOLUTION

Effective hydraulic fracturing requires careful planning and a huge fleet of pumps, equipment and people. Knowing how these costly resources can deliver maximum impact is critical. There are several critical insights which can help:

• Knowing the precise location and efficiency active fractures;

• Improving accuracy of the quantitative wellbore flow assessment;

• Evaluating flow behind the liner, and through bypassed packers;

• Validating the sealing performance of multiple barriers and confirmation of completion integrity.

TGT’s Fracture Flow and Multi Seal Integrity diagnostics can be used pre- or post-fracturing and are a viable, efficient and economic option to help operators optimise multi-stage fracturing programmes.

Also, well system flow dynamics are revealed completely, both in the wellbore and at the reservoir behind casing, enabling the operator to validate the correct operation of complex horizontal completions.

TGT consists of engineers, scientists, pioneers and innovators, who understand the importance of looking at well system dynamics consistently and proactively throughout the well lifecycle from the drilling to abandonment. TGT is not a tool supplier, instead it adopts a unique diagnostic approach that will become standard industry practice, because it allows clients to really see how their well is working.

.jpg)