Wahiba ... tailored solutions for upstream and downstream

Wahiba ... tailored solutions for upstream and downstream

Hempel is partners in all of Aramco’s upcoming greenfield, brownfield and maintenance projects through long-term contract agreements

The challenges faced by the oil and gas industry to protect assets in some of the world’s harshest environments are numerous. And with over 105 years of experience in marine and protective coatings, Hempel understands these complex needs very well.

Hempel’s extensive product range offers advanced protection for all primary asset elements within the oil and gas industry. From structural steel in new build construction to internal operating and process equipment, and extending beyond that to ongoing maintenance solutions, the company protects assets for a lifetime.

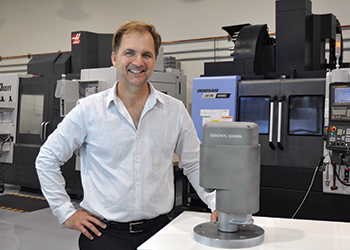

"We offer tailored anti-corrosion solutions that provide reliable, long-term protection for every aspect of your business, whether upstream or downstream, offshore or onshore, new build or maintenance," says Eyad Wahiba, Area Business Director, Saudi and Bahrain.

Hempel delivers certified products and systems that meet international standards with support from its expert coating advisors’ teams around the globe to ensure maintenance and new build projects of companies like Aramco is efficient and that coatings are applied correctly. Some of Hempel’s products include:

• Avantguard: Activated zinc primers that help reduce application times, ensure longer asset life-cycles and reduce maintenance requirements.

• Hempaline Defend: Durable internal linings helping customers manage the integrity of their process equipment and storage capacity more effectively.

• Hempaxane: These polysiloxane topcoats help reduce repainting by increased durability, gloss and colour retention.

• Hempaprime Multi 500: This fast-drying primer intermediate increases productivity without compromising on performance.

• Versiline CUI 56990: A high temperature, thick film silicone resistance to CUI, heat and thermal cycling. It allows specifiers to simplify the number of systems required, reducing the likelihood of error.

|

The King Salman International Maritime Industrial Complex |

With Aramco and Sabic, Hempel enjoys a strong long-term relationship. It is partners in all of their upcoming greenfield, brownfield and maintenance projects through long-term contract agreements.

Wahiba elaborates: "Hempel and Aramco have developed a strong relationship over the last 50 years, expressed by a direct business contract to supply Aramco requirement for their assets maintenance facilities.

Hempel has supplied to many Aramco projects. Worth mentioning here are recent projects, including the Fadhili Gas Project and Ras Tanura clean fuel project. Meanwhile. Supply to the King Salman International Maritime Industries Complex project is ongoing.

For these projects, Hempel supplied Aramco with coating systems in compliance with Aramco standards (APCS system). Some of these solutions supplied include:

• Versiline, a new solution with high value attributes for CUI (corrosion under insulation).

• Hempafire Pro 315 supply to meet Aramco’s tight project schedule in compliance with C5 requirement at the King Salman International Maritime Industrial Complex.

Wahiba says being an international coating manufacturer with local footprint allows Hempel to meet all challenges, such as tight project schedules and competitive solutions. "All this is possible due to a highly-professional team support from Aramco, Hempel SC, EPC and sub-contractors."

Hempel works closely with all major national oil companies in the Middle East region. Its 15 global R&D facilities, including one in Bahrain, allows it to work locally with clients and provide them the right solutions for their upcoming projects while ensuring environmental responsibilities are met.

Hempel’s multinational coordination teams and over 600 Frosio/Nace certified coating technical advisors are on hand to ensure top notch technical support to clients and ensure their coating projects run smoothly, from start to finish and beyond.

Hempel bring good news for GCC clients. "We have full-fledged footprint in all GCC states, and are probably the only international paint manufacturer that has six manufacturing plants within the GCC. We have also recently inaugurated our state-of-the-art manufacturing plant in Jeddah to positively contribute to the Kingdom of Saudi Arabia’s Vision 2030," says Wahiba.

Furthermore, the company is in the final stages of a new industry milestone with the groundbreaking of the most advanced solvent based coatings plant in the Middle East. "Built with an estimated cost of $8.5 million, the technologically-advanced factory represents the latest investment by Hempel group as part of its belief and contribution in the growth strategy associated with Vision 2030," says Wahiba.

He says the investment is a significant step towards maintaining and growing Hempel’s leadership position in the coating industry, and as the supplier to one of the world’s top leading oil companies, Saudi Aramco and their business partners. The new manufacturing plant, he adds, will play a significant role in boosting local economy and creating new job opportunities to local community.

About the future of the coatings industry Wahiba, says it isn’t only brighter, it’s more sustainable with fewer emissions. "We can’t make paint talk – not yet – but we believe there’s always more we can do to deliver you better-performing solutions. That’s why we’re at the forefront of new coating technologies," he states.

Hempel is on a constant journey of introducing new products into the market. It recently launched a new passive fire prevention and flooring solution to strengthen its product offering.

For example, to deal with the issue of water ingress through the coating system, a primary cause of coating failure, the company has developed Hempatop Repel 800. An advanced topcoat with water-repellent technology, Hempatop Repel 800 actively repels water from the coated surface to protect the coatings and steel beneath, leading to significantly better protection for steel in offshore environments.

Another latest Hempel solution that has found acclaim is activated zinc technology. Wahiba says it’s the most important anti-corrosive ingredient in a zinc-rich coating.

"In our award-winning Hempadur Avantguard zinc primers, more zinc is activated throughout the coating to give users superior corrosion protection in the harshest environments, from offshore oil and gas installations to heavy-duty manufacturing. They dry faster than standard zinc-rich epoxies, too, so you get best-in-class overcoating intervals and higher production speeds," he explains.

Commenting on business for Hempel, Wahiba says its oil and gas business has been consistent growing year on year despite a downward trend. He adds the Covid-19 pandemic did slightly affect growth during the months of May and June this year, but hopes to bounce back and catch up during Q3-Q4 2020.

Wahiba looks forward to a promising future for the company. "In a changing market, we are changing too, with our more focused approach to our customer’s coating requirements. We fully understand our customers’ pain areas and work proactively to anticipate their future needs. We provide coating solutions that are fast to apply, durable, cost-effective and provide advanced protection to help keep their operations running smoothly."

He expects Hempel to continue to grow market share and recognition globally and within the region.

"We always think big. Our aspiration within the next 5 years is to double our business," he concludes.

.jpg)