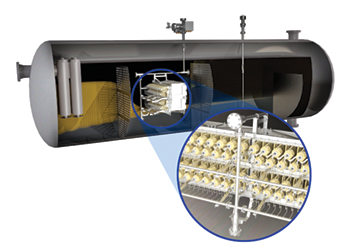

Vessel internal electrostatic coalescers

Vessel internal electrostatic coalescers

To further strengthen its presence and support in Kuwait, the specialist company is localising its operations by establishing a dedicated, experienced sales expert that will focus exclusively on the country’s market

Sulzer, a specialist in pumping solutions, rotating equipment maintenance and services as well as separation, reaction, and mixing technology, is in the process of expanding its installation services for Kuwaiti customers involved in both upstream and downstream operations.

"In particular, Sulzer is able to supply and install high-quality systems and entire plants in a very short time, thanks to its capabilities in designing skid-mounted equipment," says S Ramann, Head of Sales, Sulzer Chemtech Middle East.

As a result, businesses can benefit from up to 20 per cent faster delivery times as well as substantially lower investment costs, when compared to traditional assemblies, he points out.

One of the key new offerings from Sulzer to the Kuwaiti market is the VIEC solution, which has already raised interest in the country. In fact, Sulzer is in the process of supplying a number of VIECs to one of the largest oil companies in Kuwait. This technology will help the oil giant to achieve better separation efficiency whilst optimising energy consumption, he says.

This leading oil company is not the only one interested in VIEC. Sulzer is currently involved in many ongoing discussions with different end users in Kuwait to deliver this, and other cutting-edge solutions for other mass transfer applications, notes Ramann.

Sulzer has been enjoying a growing demand for its solutions and services. It has clearly seen substantial expansion both globally and in the Middle East. With Kuwait’s upstream sector seeing $12.3 billion worth of projects, Kuwait is a particularly important region for Sulzer Chemtech.

"We are a leading separation and mixing technologies company. Our strategy is to support the local market with high-quality products and local points of contact backed up by a global footprint," he says.

To further strengthen its presence and support in Kuwait, Sulzer is localising its operations by establishing a dedicated, experienced sales expert that will focus exclusively on the country’s market.

Sulzer has a number of ongoing projects in Kuwait that addresses the different needs of the local oil and gas process industry. Following the recent investments in refineries to expand the downstream operations in Kuwait, Sulzer is supplying column internals for multiple units. These contracts are being executed through assigned global engineering, procurement and construction (EPC) organisations.

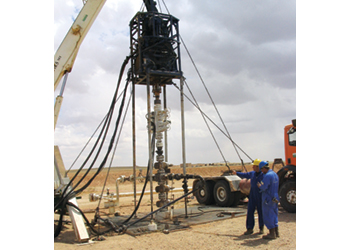

In addition, Sulzer is providing new trays, packing and other column internals to existing plants. When urgent maintenance activities are needed, Sulzer can mobilise its global network of service centres and promptly deliver key pieces of equipment from its nearby manufacturing facilities.

Besides providing new units and replacement parts, Sulzer is also supporting its customers with a reliable installation service. Sulzer, with its vast experience in designing mass transfer equipment and handling innumerable plant turnarounds, is able to assess the condition of existing columns and internals as well as suggesting the most suitable maintenance activities required.

As a result, customers can reap the many benefits of a single point of contact, such as streamlined operations. These advantages are particularly important during plant turnaround, when it is crucial to minimise downtime.

"Our current projects in Kuwait support local businesses in developing new facilities for oil and gas processing, keep existing plants running efficiently, as well as boosting their productivity, capacity and efficiency by means of well-designed revamps."

"We expect to finish the ongoing projects in Kuwait later this year. Upon completion, we do anticipate a fresh surge of investment in upstream projects as well as downstream. As fast and efficient decision making will become even more crucial to support these new projects, we feel we are making the right move by setting up a dedicated team resource in the region," says Ramann.

Most of the recent contracts have been executed through global EPC companies. Therefore, efficient project management, quality control and logistics planning were a must in order to succeed. Sulzer is well equipped to address any unexpected issues and challenges; thus, it can consistently deliver high-quality solutions.

Sulzer’s proven track record of delivering state-of-the-art mass transfer solutions for the upstream oil and gas segment is one of its strongest competitive advantages in Kuwait and worldwide, observes Ramann. Businesses in the sector can benefit greatly from Sulzer’s extensive portfolio of products, technologies and services for upstream operations, as well as its ability to develop bespoke systems.

The company conducts extensive testing in dedicated centres to ensure customers receive high-performance, customised solutions. To assess oil and gas process equipment, the company uses a state-of-the-art, large scale test site at Process Laboratories The Netherlands (ProLabNL). This facility can simulate real high- or low-pressure oilfield conditions. Upon successful completion of appropriate testing and validation, ProLabNL can provide independent third-party certifications.

Sulzer supports both the upstream and downstream segments of the oil and gas industry with mass transfer solutions and services. Its product offering incorporates the latest technological advancements and ranges from single separation components, such as column internals, to complete and integrated separation systems.

Key upstream technologies offered by Sulzer include vessel internal electrostatic coalescers (VIEC™) and compact mass transfer and inline separation (cMIST) systems. The former uses alternating high voltage electrical fields to conduct liquid-liquid separation with high accuracy, while the latter can be applied to onshore and offshore gas dehydration applications.

Currently, Sulzer benefits from local representative partners to support its customers in the country. "Strong partnerships with local businesses in Kuwait are vital for Sulzer and we are always interested in new collaborations," he says.

As a continually growing engineering major that operates on a global scale, Sulzer is interested in developing and integrating new technologies by means of meaningful collaborations. Therefore, Sulzer is willing to support its customers by exploring different forms of cooperation in the region, he adds.