Vezvaei ... at the helm of vigorous development

Vezvaei ... at the helm of vigorous development

The company has several running contracts. Some are spanning across several years and some others are shorter. The latest additions to the list are two multiyear contracts in Kuwait’s power sector with the Ministry of Electricity and Water

Having successfully expanded its footprint in Egypt, Turkey and elsewhere in the region, Bilfinger, a leading global player in engineering and process plant services, sees more growth opportunities in the Middle East especially Kuwait, where it had set up operations some 51 years ago.

As Kuwait and the rest of the Middle East move closer towards a more sustainable future, now more than ever, there is a very clear demand from asset owners for increased efficiency, enhanced productivity of their value streams and commercially viable environmental solutions to address their carbon footprint, says Ali Vezvaei, Executive President of Bilfinger Middle East.

"This push towards a more efficient and clean industrialisation resonates very well with our strategic focus and portfolio development; whether through digitalisation or FGD (Flue Gas Desulphurisation) or BMC (Bilfinger Maintenance Concept), these are growth opportunities for Bilfinger, where we expect to open new market fronts and promote opportunities for further collaboration and growth," he says.

|

Bilfinger is working on a number of high-profile projects in the region. |

Having rolled out its digital services in the Middle East, Bilfinger is well on track with its strategic objectives. Multiple EPC awards in the hydrocarbon sector, major engineering framework agreements and several long terms maintenance service contracts underline the company’s progress in the recent past.

"This is however just the beginning. The Middle East region offers unique opportunities for many years to come and we at Bilfinger are proud looking back and excited looking forward," he observes.

"We are currently executing multi-year maintenance and services contracts in several of Kuwait’s industrial sites, and our presence in these plants provides us with a key understanding of their needs in terms of efficiency and sustainability," he points out.

The company has several running contracts. Some are spanning across several years and some others are shorter. The latest additions to the list are two multiyear contracts in Kuwait’s power sector with the Ministry of Electricity and Water.

|

Bilfinger is working on a number of high-profile projects in the region. |

The combined order value is more than $75 million. One order is for the mechanical maintenance of a power plant and seawater desalination facilities over a five-year period. The other is a three-year contract to repair and replace smokestacks at another power plant.

There are also some critical maintenance works in the petrochemical sector such as cracking furnaces repair, where Bilfinger leverages its knowhow, local competence and skilled resources and its German DNA in quality and time schedule, he explains.

Having set roots in Kuwait more than half a century ago, in 1968, Bilfinger has had decades of experience delivering integrated projects and lifecycle services to Kuwait’s industrial plants – mechanical, electrical and I&C (instrumentation and control) maintenance involving boilers, valves, and rotating equipment, among others.

"Now we are looking to bring maintenance to the next level through our globally recognised solutions such as BMC and BCAP (Bilfinger Connected Asset Performance)," he says.

BMC and BCAP provide a holistic solution to process plants looking to increase overall equipment efficiency and effectiveness, reduce unscheduled downtimes and ultimately to transition from reactive to prescriptive maintenance.

This is what the company has been providing to customers around the globe for several years and they tie quite nicely into Kuwait’s strategic vision and where its industry is headed.

|

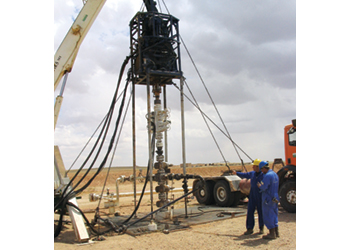

The company executing the PIC turnaround in Kuwait |

Last but not least is Bilfinger’s extensive Feed and engineering services. Started nearly 45 years ago in the region, Bilfinger Tebodin is reliable engineering partner of choice to many valuable customers, both national oil companies as well as international oil companies.

Bilfinger’s stint in Kuwait started as a contractor for a major power plant. Since then, it had successfully delivered a full catalogue of projects and services to the country’s energy sector and plant operators – ranging from maintenance, upgrades, enhancements to plants life cycle extensions – the list is more than 50 years long.

Half a century later, Kuwait not only remains to be a key energy market for Bilfinger, but also provides new strategic opportunities in the hydrocarbon sector. The country’s aging infrastructure and drive for efficiency on the one hand and Bilfinger’s portfolio as a reliable and trusted lifecycle services partner in the process industry on the other hand give rise to great range of opportunities for optimisation in the OPEX hemisphere, he notes.

"The focus of our operations in Kuwait has been on maintenance, improving plant performance and cost optimisation – creating more value from clients’ assets or reducing the cost of delivering what they do," he maintains.

Referring to Petrochemical Industries Company’s (PIC) turnaround which Bilfinger had executed in Kuwait, Vezvaei says: "It was a privilege to have delivered such a successful project to PIC, which has been a client since 1971."

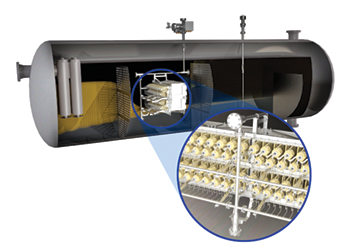

The target was to increase the output of a 40-year-old waste heat boiler for steam production by nearly 50 per cent! The waste heat from an auxiliary boiler and a neighbouring independently-fired superheater was used to pre-heat the feed water.

In less than six months, Bilfinger designed and delivered components to increase output and installed them within the 28-day shutdown period.

The challenge to the company was to ensure coordination of the complex execution – six Bilfinger companies were involved in the turnaround and at peak times, up to 140 colleagues were on the job site.

"In the end, while increasing the capacity, we managed to reduce more than 10 per cent in fuel consumption for steam generation. Consequently, the environmental footprint was also optimised as our design could cut back on CO2 emissions and waste heat. This is what we call a real Win-Win!," he says.

On introduction of new technologies in the region, he says the economic reforms and the strategic transformation in several countries in the Middle East on the one hand and the demographic dynamics on the other hand is driving a shift in the energy market.

It is no longer just the green field Capex to address the change in demand profile; rather an integrated view on "From Molecules to Megawatts" has begun to prevail. This is a departure from the purely hydrocarbon-reliant industries to a new focus towards building integrated, efficient and sustainable energy systems.

"This is where every molecule and every megawatt counts". Bilfinger has technologies and solutions that are specifically geared to address these opportunities.

"We have proven solutions to enhance waste heat recovery. This is the heat re-claimer technology enabling an already-efficient combined-cycle power plant to recover some more percentages of efficiency, for example."

In Kuwait, Bilfinger recently installed low NoX burners at Sabiya Power Station to enhance efficiency and reduce emissions for eight boilers.

In the UAE, looking at the significant thermal generation capacity, the company could build a bridge between concentrated solar and existing thermal generation units through another innovative technology that Bilfinger has developed - HyCSP.

Another sector that needs a thorough reassessment is the region’s energy-intensive water desalination processes. Here, Bilfinger is leading the way with a number of patented innovations: Improved Brine Recycle Circuit (IBRC) that increases production capacity by up to 30 per cent, and the Steam Recirculation System (STRS), which delivers an increase of plant GOR by up to 10 per cent. In another innovative front, Bilfinger together with its technology partners have completed two pilot project in Forward Osmosis (FO).

On even more advanced offerings, Bilfinger is an active proponent of the region’s industrial digital transformation. "We are very much focused on delivering digital innovations to the process industries: asset digital twins, the new knowledge-platform Industrial Tube, next-gen plant documentation solution PIDGraph, and of course BCAP and BMC for cost reduction, efficiency optimisation and all in all driving productivity."