R&DC ... a world-class research institution

R&DC ... a world-class research institution

THREE high-profile Research and Development Centre (R&DC) projects and technologies represent the innovation and dedication to breakthrough science that have made Saudi Aramco’s R&DC a world-class centre of research and development.

They are computer modelling of separation flows, an online salt-in-crude analyser and a desert ray/laser finger printing instrument.

New developments in the projects were presented to senior vice president of engineering and project management Salim Al Aydh and engineering vice president Abdullah Al Saadan during a recent visit to the centre.

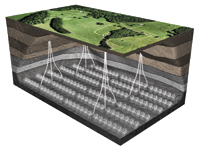

Crude oil separation is achieved through the use of gravity along a series of separation vessels. Improving the efficiency of gravity separation improves the overall process, and according to project leader Regis Vilagines that’s the goal of the computer modelling of separation flow project.

Vilagines explains that the group has developed the world’s first three-phase separation flow model and is using it to simulate various in-tank conditions that impact the separation of whole crude into gas, water and oil. The model has also led to the design-stage optimisation of an innovative inlet device for multiphase separators, which Vilagines and his team say can lead to as much as 20 per cent performance improvement.

The next step in the project, according to Vilagines, is to capture knowledge and develop this in the form of a separation software tool, continue to validate model results against test data with Saudi Aramco crude oils and then field test the inlet device concept.

“We need to prove the concept in a timely manner, so we can plan additional expansion as the water cut increases,” notes Al Saadan. “This is the kind of innovation which will have a company-wide effect when we can eventually install it across the company.”

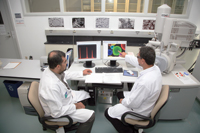

Sebastien Duval, lead researcher for the on-line salt-in-crude analyser project then explained that there is no reliable salt-in-crude analyser available in the marketplace – a fact his team is hoping to remedy.

The team recently concluded a seven-month field test of the conductivity-based prototype analyser, and will build and field demonstrate conductivity-based preindustrial prototypes at various facilities. Also on the slate is the building and field testing of an innovative single-solvent prototype, the first of its kind in the industry.

Ez zat Hegazi, team leader for the laser oil fingerprinting technology project, presented his team’s laser-based technology for characterising oil products. It has already been granted or has in process nine patents, and has a seemingly endless list of potential applications – everything from crude oil and refined product identification to fuel additive monitoring, detection of smuggling and oil spill source investigation.

DesertRay 1, an instrument that delivers the technology, has already been developed and is being used in the laboratory. DesertRay 2, a fuel-mixing detector, and GulfRay, a remote sensing device, are in progress, and a blend replicator is scheduled for future development.

“The importance of what has been achieved and the potential for this technology represent a real success for R&DC,” says Hegazi. “This is what it is all about – creativity and innovation and determining how we can leverage a technology.”

Al Aydh agrees. “This is great work,” he says. “It has the potential to go beyond oil and refined products. I believe it can be developed further, and that is where we should focus.”

He adds: “I think there are lots of activities taking place (in R&DC) that will result in breakthroughs in helping us to be able to optimise and to work on operational issues that hopefully will be solved by these ideas rather than spending a lot of money.”

But optimisation of systems is just one angle. “The other angle,” Al Aydh says, “is taking these breakthrough ideas and looking at the applications and then creating manufacturing and other businesses around us based on these ideas being developed by R&DC.”

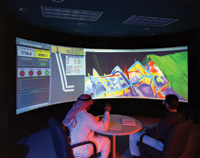

During the recent visit to R&DC by senior management, 21-year-old Thamer Al Otaibi found himself elbow-to-elbow with senior vice president Al Aydh, demonstrating some of the science behind his team’s computer modelling of separation flows.

It was a situation that might have prompted nerves in some but not Al Otaibi. “I have seen my colleagues do (demonstrations) many times,” he explains, “but I am fresh – only six months – so I did many dry runs in my head and with my colleagues.”

That support, says Al Otaibi, makes R&DC the “best of Saudi Aramco.”

“I can learn much here because R&DC gives me the chance to learn, to develop and to improve myself,” he says. As evidence, Al Otaibi pointed to his newfound knowledge of and training on various pieces of equipment, knowledge gained from e-learning courses he’s taken and his leadership role when it comes to safety in his group, as well as the chance to visit outlying Saudi Aramco facilities.

.jpg)