The new generation Gammapilot FMG50

The new generation Gammapilot FMG50

The device allows operators to communicate with the sensor using Bluetooth technology and the Smart Blue app from Endress+Hauser, making available once hard to obtain product and diagnostic data

Gamma (radiometric) solutions are mainly used in applications where other measurement principles will not work. With 70,000 solved applications and almost 60 years of experience, radiometry is an important pillar in Endress+Hauser's portfolio, says Sivaji Nemalipuri, Industry Manager at Endress+Hauser.

The new generation device, Gammapilot FMG50, surpasses previous radiometric instruments in terms of safety, compactness and user-friendliness, and offers outstanding customer benefits, which include:

• Cost and time saving by minimising commissioning and maintenance efforts through the use of the world’s first true 2-wire loop powered gamma compact transmitter.

• Increased plant safety, efficiency and availability as this device is developed according latest SIL standard IEC 61508 (SIL2/3).

• Reduction of verification efforts and minimising unplanned plant shut-downs, thanks to Heartbeat Technology.

• Lower installation and maintenance efforts needed thus ensuring reliable measurements even at extreme conditions using special material without additional cooling.

Further elaborating on the benefits and explaining the fields of application for this innovative device, Sivaji says: "The Gammapilot is used in process vessels such as reactors, separators, cyclones and autoclaves, and measures in both liquids and solids.

"In addition to the detection of the level and point level, it is also suitable for density and interface measurements. It works where other measuring principles cannot be applied due to corrosion, abrasion, viscosity or toxicity."

Nemalipuri says the new Gammapilot FMG50 is suitable for primaries, metal applications, oil and gas and chemicals. Due to its installation from the outside, there are no restrictions even when high temperature and high pressure occur.

INNOVATIVE 2-WIRE TECHNOLOGY

In many industries, 2-wire technology has been the preferred type of instrumentation for quite a few years. In the field of radiometry, technological hurdles in high-voltage generation prevented the development of a 2-wire compact transmitter so far.

Until now, the components of the detectors required more energy so that a direct connection to a control system (PLC) was not possible. Even conventional 2-wire devices could only be used with an external power supply due to the separate transmitter system.

The Gammapilot FMG50 is the first 2-wire loop-powered compact transmitter in the market; it uses a unique, patented high-voltage generation and requires only a fraction of the energy of its predecessor to reach the same measurement performance. This revolutionises radiometric measurement and offers valuable advantages over conventional 4-wire and 2-wire devices.

As additional installations and wiring for a supply voltage are no longer needed, considerable cost savings are achieved over the entire lifecycle of the measuring point. This eliminates purchase and installation costs for additional cables and reduces the planning effort to design the power supply. In addition to cost advantages, the 2-wire concept offers benefits for safe and simple maintenance.

DIGITAL POTENTIAL

With the latest generation of Gammapilot, operators can communicate with the sensor using Bluetooth technology and the Smart Blue app from Endress+Hauser. The app makes all product and diagnostic data available that could previously only be determined with great effort.

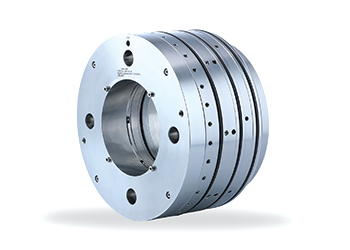

|

A Gammapilot FMG50 application |

Another benefit of the Bluetooth functionality is the remote commissioning of the device. This is particularly relevant for measuring points that are difficult to access.

The diagnostic function of Heartbeat Technology indicates the status of the Gamma pilot. The performance of the instrument is determined by more than 50 parameters. The permanent self-diagnostics guarantees safe system operation with extended proof test cycles.

In addition to the current device diagnostics, verification via Heartbeat Technology enables complete documentation without process interruption. The automatically generated test protocol serves as proof of compliance with regulations and laws.

The intuitive Heartbeat Verification Wizard guides the operator step-by-step through the test process, while the Heartbeat Technology monitoring function supports predictive maintenance. This ensures the user receives valuable information about the operating time of the radiation source for the corresponding application as well as about the lifetime of the sensor.

Furthermore, the instrument data enables trend detection. This means that maintenance measures can be planned and implemented in a targeted manner and plant downtimes can be avoided.

FUNCTIONAL DEVICE SAFETY

The Gammapilot FMG50 has been developed according to IEC 61508 for use in SIL2 and SIL3 applications and is currently the safest radiometric device on the market. It offers the SIL functionality for all measuring tasks (level, point level, density and interface).

The newly implemented, user-friendly SIL Wizards reduce systematic and human errors. Safety-relevant parameter settings can already be confirmed during commissioning, and continuous device diagnostics of safety-relevant functions take place during operation.

The SIL proof test wizard guides step-by-step through the test procedure and automatically generates a report. This simplifies the work for the user and creates freedom for the optimization of further processes.

USE WITHOUT COOLING

In applications with high temperatures, conventional instruments require additional water cooling to ensure a trouble-free measurement. The Gammapilot FMG50 solves this challenge with a high-quality sensor material.

In addition, the innovative sensor design ensures the minimal self-heating of the device electronics and thereby contributes to the use without cooling. By eliminating the need for water cooling, planning, installation and operation costs can be saved.