Faccin's three-roll plate roll HAV series

Faccin's three-roll plate roll HAV series

Part of its strategy to invest in training, digitalisation, and the purchasing of new machinery, Italian steel manufacturing specialist Comeca Tecnologie has chosen the plate rolling system built by Faccin.

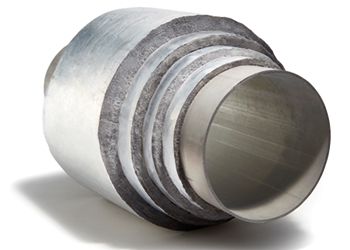

The plate roll, which offers extreme ease of use and high performance, will allow Comeca Tecnologie to roll products in-house with thicknesses up to 100 mm and as a result greatly improve the lead time offered to its customers.

Comeca Tecnologie has been active for more than 50 years in the steel industry, the non-ferrous metal industry and in the energy sector. It designs and manufactures systems, spare parts and equipment for steelworks, rolling mills, continuous casting and fume treatment plants, and is active both nationally and internationally, with foreign customers located mainly in Europe.

Comeca Tecnologie offers its customers customised solutions and services by analysing the different needs and consequently diversifying its products.

Thanks to this flexibility, achieved through highly-trained technical staff, the company has conquered a particular niche in the market and is, therefore, able to consistently respond with very high-quality standards, to the customers’ requests.

Right from the start, Comeca Tecnologie’s experienced staff found Faccin’s plate rolling system very easy to use. In fact, it took only two days of training with the Faccin Group technicians to learn how to completely manage the system.

Finally, investing as well in industry 4.0 features, has made the purchase even more profitable.

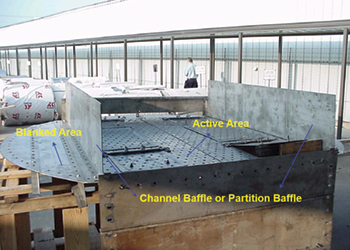

Comeca Tecnologie will use the plate roll for the processing of multiple manufactured goods, such as scrap baskets, ladles, slag pots, EAF electric furnaces, tanks, cyclones, ducts for dedusting systems, quench towers, etc.

This new machine will bring numerous benefits, including the reduction of fabrication time and the simplification of operations.

Even less experienced operators will be able to use the plate roll, given the simplicity for memorising the rolling steps.

In addition, the quality increase of the pre-bending process on the steel plates is a positive plus.

FACCIN HAV TECHNOLOGY

HAV is a series of three-roll variable geometry plate rolls with high rolling power combined with maximum bending precision, and an ideal combination of performance and versatility.

Designed, built and marketed by Faccin since the 1970s, the HAV models offer a very fast and safe pre-bending phase.

Thanks to their special configuration, the three rolls of the machine move independently; the upper roll with vertical movement and the lower rolls with horizontal movement, allowing the operator to adjust the distance between the lower rolls and the distance between the bending points as needed.

By reducing the distance to the bending point to a minimum, an excellent traction of the plate together with better-quality of the pre-bending are obtained thus minimising the length of the flat edge.

The maximum distance between the lower rolls, on the other hand, ensures an enormous rolling capacity.

Faccin Group is a leading global metal forming machine producer that manufactures and commercialises three great brands, Faccin, Boldrini and Roundo, offering the widest range of plate rolls, angle rolls, dished head lines and special machines. The group have successfully installed over 30,000 machines worldwide.

Faccin Group exhibited its technology at the Blechexpo Stuttgart 2021 Trade Show from October 26-29.